Anhui Feichun Kabel Khusus Co., Ltd

Type SHD-GC Heavy Duty Cable Three-Conductor Round Portable Power Cable CPE Jacket 15kV to ICEA S-75-381

Feichun Type SHD-GC Heavy Duty Cable Three-Conductor Round Portable Power Cable CPE Jacket 15kV to ICEA S-75-381

Applications :

These heavy duty cables are designed for applications such as longwall shearers, continuous miners and mobile equipment such as shovels, dredges and drills.

Standards :

ICEA S-75-381/NEMA WC 58

ASTM B 172

ASTM B 33

CAN/CSA C22.2 No. 96 |  |

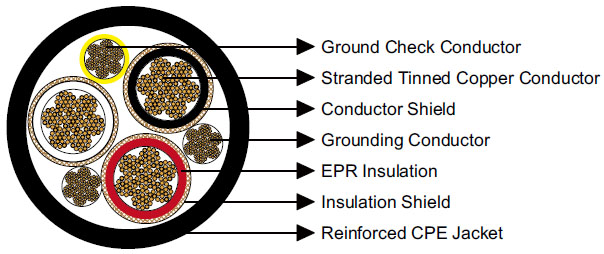

Construction :

Conductor | Stranded annealed tinned copper conductor. |

Conductor Shield | Conducting layer. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Conducting tape + Tinned copper/textile braid. |

Ground Check Conductor | Tinned copper with a yellow polypropylene insulation. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Reinforced extra-heavy-duty Chlorinated Polyethylene (CPE), black. |

Options :

Other jacket materials such as CSP/PCP/NBR/PVC/TPU are available upon request.

Two-layer jacket with reinforcing fibre between the two layers can be offered as an option.

Mechanical and Thermal Properties :

Minimum Bending Radius: 8×OD.

Maximum Conductor Operating Temperature: +90℃.

Dimensions and Weight :

Construction | No. of | Grounding | Ground | Nominal Insulation | Nominal Jacket | Nominal Overall | Nominal Weight | Ampacity | ||||

No. of cores | - | AWG/ | AWG/ | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×2 | 259 | 6 | 8 | 0.210 | 5.3 | 0.235 | 6.0 | 2.41 | 61.2 | 3572 | 5529 | 164 |

3×1 | 259 | 5 | 8 | 0.210 | 5.3 | 0.235 | 6.0 | 2.52 | 64.0 | 4060 | 6042 | 187 |

3×1/0 | 259 | 4 | 8 | 0.210 | 5.3 | 0.250 | 6.4 | 2.64 | 67.0 | 4495 | 6927 | 215 |

3×2/0 | 329 | 3 | 8 | 0.210 | 5.3 | 0.250 | 6.4 | 2.73 | 69.3 | 5010 | 7783 | 246 |

3×3/0 | 413 | 2 | 8 | 0.210 | 5.3 | 0.265 | 6.7 | 2.90 | 73.7 | 5995 | 8922 | 283 |

3×4/0 | 532 | 1 | 8 | 0.210 | 5.3 | 0.265 | 6.7 | 3.05 | 77.5 | 6860 | 10209 | 325 |

Ampacity-Based on a conductor temperature of 90℃ and an ambient air temperature of 40℃, per ICEA S-75-381.

When underground and surface mining operations demand high-voltage power, extreme mechanical strength, and uncompromising safety, the Type SHD-GC Heavy Duty Cable stands out as a proven solution. Designed in accordance with ICEA S-75-381, this 15 kV three-conductor round portable power cable with a reinforced CPE jacket is widely used on longwall shearers, continuous miners, and heavy mobile equipment.

But what exactly makes a Type SHD-GC cable different, and how do you know if it’s the right choice for your mining operation—especially in demanding environments?

What Is a Type SHD-GC Heavy Duty Cable According to ICEA S-75-381?

A Type SHD-GC cable is a shielded, heavy-duty portable mining power cable specifically engineered for medium-voltage applications up to 15 kV. The designation typically indicates:

SHD – Shielded Heavy Duty

GC – Includes both grounding conductor and ground-check conductor

Under ICEA S-75-381 / NEMA WC 58, SHD-GC cables are intended for portable power distribution where cables are frequently dragged, bent, reeled, or exposed to impact, abrasion, moisture, oil, and chemicals.

Where Are Type SHD-GC 15 kV Heavy Duty Cables Commonly Used?

Which Mining Equipment Requires SHD-GC Cables?

Longwall shearers

Continuous miners

High-power mobile shovels

Dredges and drills

Large underground mobile substations

How Does SHD-GC Compare with Other Mining Cable Types?

Feature | SHD-GC | SHD-G | Type G-GC |

|---|---|---|---|

Voltage rating | Up to 15 kV | Typically ≤ 8 kV | ≤ 5 kV |

Insulation | EPR | EPR | EPR/PVC |

Shielding | Full | Partial | Limited |

Ground-check | Yes | Optional | Yes |

Typical use | Heavy MV mining | Medium duty | Light to medium duty |

Conclusion:

For high-voltage, safety-critical mining applications, SHD-GC is the preferred choice.

What Are Best Practices for Installing SHD-GC Heavy Duty Cables?

Respect the minimum bending radius (8×OD)

Avoid sharp edges and pinch points

Use proper cable handling equipment for heavy weights

Ensure ground-check continuity testing before energising

Follow mine-specific safety and lock-out procedures

Correct installation directly impacts service life and operational safety.

Frequently Asked Questions (FAQ)

Can Type SHD-GC cables be used above ground?

Yes. While designed for underground mining, they are also suitable for harsh surface applications involving mobile equipment.

Is a CPE jacket better than PVC for mining?

Absolutely. CPE offers superior resistance to oils, chemicals, abrasion, and flame spread.

Can jacket materials be customised?

Yes. Options such as CSP, PCP, NBR, PVC, TPU, or dual-layer reinforced jackets are available on request.

Why is a ground-check conductor mandatory in many mines?

It ensures grounding integrity before power is applied, significantly reducing electric shock risk.

How Do You Choose the Right SHD-GC Cable for Your Operation?

Selecting the correct Type SHD-GC Heavy Duty Cable isn’t just about voltage—it’s about safety, durability, compliance, and long-term reliability.

If you're powering high-demand mining equipment and need:

ICEA S-75-381 compliance

Custom conductor sizes or jackets

👉 Consult a professional mining cable manufacturer or technical specialist to specify the optimal SHD-GC solution for your site.

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: