Anhui Feichun Kabel Khusus Co., Ltd

Type SHD-GC 25kV Three-Conductor Round Portable Power Cable TPU Jacket for Heavy Mobile Equipment

Feichun Type SHD-GC 25kV Three-Conductor Round Portable Power Cable TPU Jacket for Heavy Mobile Equipment

Applications :

These heavy duty cables are designed for heavy mobile equipment such as drag lines, shovels, dredges,drills and for power feeders.

Standards :

ICEA S-75-381/NEMA WC 58

ASTM B 172

ASTM B 33

CAN/CSA C22.2 No. 96 |  |

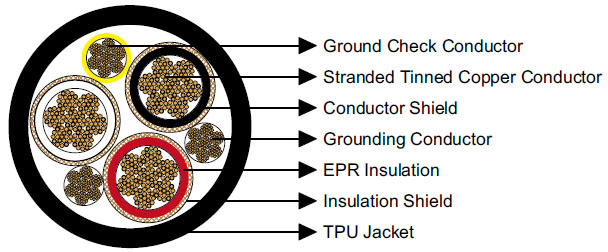

Construction :

Conductor | Stranded annealed tinned copper conductor. |

Conductor Shield | Conducting layer. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Conducting tape + Tinned copper/textile braid. |

Ground Check Conductor | Tinned copper conductor with a yellow polypropylene insulation. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Thermoplastic Polyurethane (TPU) Jacket, black. |

Options :

Other jacket materials such as CPE/CSP/PCP/NBR/PVC are available upon request.

Two-layer jacket with reinforcing fibre between the two layers can be offered as an option.

Mechanical and Thermal Properties :

Minimum Bending Radius: 8×OD.

Maximum Conductor Operating Temperature: +90℃.

Dimensions and Weight :

Construction | No. of | Grounding | Ground | Nominal Insulation | Nominal Jacket | Nominal Overall | Nominal Weight | Ampacity | ||||

No. of cores | - | AWG/ | AWG/ | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×1 | 259 | 5 | 8 | 0.260 | 6.6 | 0.265 | 6.7 | 2.95 | 74.9 | 4410 | 6561 | 191 |

3×1/0 | 266 | 4 | 8 | 0.260 | 6.6 | 0.265 | 6.7 | 3.05 | 77.5 | 4866 | 7240 | 218 |

3×2/0 | 323 | 3 | 8 | 0.260 | 6.6 | 0.280 | 7.1 | 3.20 | 81.3 | 5560 | 8272 | 249 |

3×3/0 | 418 | 2 | 8 | 0.260 | 6.6 | 0.280 | 7.1 | 3.33 | 84.6 | 6192 | 9213 | 286 |

3×4/0 | 532 | 1 | 8 | 0.260 | 6.6 | 0.295 | 7.5 | 3.50 | 88.9 | 7110 | 10578 | 327 |

Ampacity-Based on a conductor temperature of 90℃ and an ambient air temperature of 40℃, per ICEA S-75-381.

What Is Feichun Type SHD-GC 25kV Cable and Where Is It Typically Used?

Type SHD-GC 25kV is a heavy-duty, medium-voltage portable power cable designed for supplying electricity to large, continuously moving mining equipment.

Typical application environments include:

Open-pit and underground mines

High-power mobile equipment zones

Areas exposed to abrasion, oil, moisture, UV, and mechanical stress

Typical equipment powered by SHD-GC 25kV:

Draglines

Electric shovels

Dredges

Rotary and down-the-hole drills

Mobile power feeders

The 25kV voltage rating allows efficient long-distance power transmission while minimizing current and conductor losses—critical in large mining operations.

How Is a Type SHD-GC 25kV Portable Power Cable Constructed?

The performance of SHD-GC cables comes directly from their multi-layer, function-driven construction, optimized for electrical safety and mechanical durability.

What Kind of Conductor Does SHD-GC 25kV Use?

Stranded annealed tinned copper

High strand count improves flexibility

Tin coating enhances corrosion resistance in humid and chemically aggressive environments

This conductor design is especially important for constant bending and dragging conditions.

Why Is a Conductor Shield Necessary in 25kV Cables?

A conducting layer is applied over each conductor to:

Smooth the electrical field

Reduce partial discharge

Extend insulation life at high voltage levels

This is a critical safety feature for 25kV-class mining cables.

What Makes EPR Insulation Suitable for SHD-GC 25kV?

The insulation material is Ethylene Propylene Rubber (EPR), chosen because it offers:

Excellent dielectric strength

High resistance to thermal aging

Flexibility at low temperatures

Stable performance up to 90°C conductor temperature

EPR is widely recognized as the preferred insulation for portable MV mining cables.

How Do Insulation Shielding and Grounding Improve Safety?

The insulation shielding system consists of:

Conducting tape

Tinned copper or textile braid

Together with:

Grounding conductor (tinned copper)

Ground check conductor (yellow polypropylene insulated)

This design ensures:

Reliable grounding continuity

Compatibility with ground-check monitoring systems

Compliance with ICEA and CSA mining safety practices

Why Choose a TPU Jacket for Heavy Mobile Equipment?

What Advantages Does a TPU Jacket Offer Over CPE or PVC?

The outer jacket of this SHD-GC cable is Thermoplastic Polyurethane (TPU), which provides:

Outstanding abrasion resistance

High tear and cut resistance

Excellent oil, grease, and chemical resistance

Superior flexibility compared to CPE

Long service life under dragging and crushing loads

This makes TPU particularly suitable for heavy mobile equipment with frequent relocation.

Optional Jacket Configurations

Feichun also offers:

Alternative jackets: CPE, CSP, PCP, NBR, PVC

Two-layer jackets with reinforcing fiber for extreme mechanical abuse

What Are the Best Installation Practices for SHD-GC 25kV Cables?

Recommended Installation Guidelines

Always respect minimum bending radius (8×OD)

Avoid sharp edges and uncontrolled dragging

Use cable rollers or skid plates where possible

Ensure proper termination with stress cones for 25kV

Regularly inspect jacket condition and grounding continuity

Correct installation significantly extends service life and improves safety.

Frequently Asked Questions (FAQ)

Is SHD-GC 25kV suitable for continuous flexing?

Yes. Its stranded copper conductor, EPR insulation, and TPU jacket are designed specifically for continuous movement.

Can SHD-GC 25kV be used outdoors?

Absolutely. TPU offers excellent UV, moisture, and weather resistance.

Is this cable compliant with international standards?

Yes. It complies with ICEA S-75-381 / NEMA WC 58, ASTM B172, ASTM B33, and CAN/CSA C22.2 No. 96.

Can I request custom jacket or reinforcement options?

Yes. Two-layer jackets with reinforcing fiber are available upon request.

Why Choose Feichun for SHD-GC 25kV Portable Power Cables?

Feichun combines:

Proven mining cable engineering

International standard compliance

Flexible customization capability

Real-world mining project experience

If you are selecting a 25kV portable power cable for heavy mobile equipment, Feichun SHD-GC provides a balanced solution of safety, durability, and electrical performance.

👉 Need help selecting the right SHD-GC 25kV size or jacket option for your mining project?

Contact Feichun’s technical team for engineering support, datasheets, and project-specific recommendations.

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: