Anhui Feichun Special Cable Co.,Ltd Li.wang@feichuncables.com

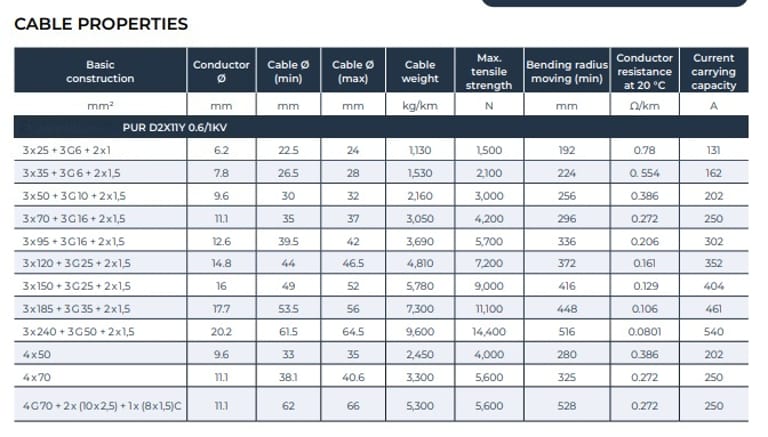

PUR D2X11Y 1 KV REELING CABLE FOR DRILLS AND LHD

Feichun PUR D2X11Y 1 KV REELING CABLE FOR DRILLS AND LHD

Application:

This is a flexible low voltage reeling cable with optimized dimensions and flame retardant, halogen-free polyurethane outer sheath. The cable is used as power supply for underground mining and tunnelling equipment and designed for frequently changing dynamic loads, such as reeling operation on drilling machines, scoops and LHD’s. Suitable to withstand the high mechanical stresses caused by reeling application and the abrasion to be expected in trailing operation.

Structure:

1. Conductor Finely stranded copper, bare, class 5

2. Core insulation XLPE

3. Control core

4. Split earth conductor

5. Core arrangement Three main conductors laid-up together with split earth conductor and control cores in the interstices. Cores twisted with very short length of lay Main cores: brown, black, grey Control cores: blue, white

6. Inner sheath Halogenfree polymer

7. Outer sheath Polyurethane (PUR)

STANDARDS / APPROVALS:

DIN EN 60228/ IEC 60228 / VDE 0295 Conductor

DIN VDE 0298-300 Core identification

IEC 60502-1 Compound

DIN VDE 0298-4 Electrical parameters

DIN EN 60332-1-2 / IEC 60332-1-2 Fire performance

THERMAL PARAMETERS:

Max. conductor temperature 90 °C

Max. conductor temperature at short circuit 250 °C

Ambient temperature fix installation (min) -40 °C

Ambient temperature fix installation (max) 80 °C

Ambient temperature flexible installation (min) -30 °C

Ambient temperature flexible installation (max) 80 °C

CHEMICAL PARAMETERS:

Halogen free Yes

Ozone resistance Yes

Resistant to UV Yes

Max. water depth 10 m

MECHANICAL PARAMETERS:

Torsional stress +/- 50 °/m

Permanent tensile strength (rule) 20 N/mm²

Travel speed Reeling operation underground: 60 m/min

Bending radius (rule) Acc. to VDE 0298-3:

4 x D fixed installation

8 x D reeling operation

ELECTRICAL PARAMETERS:

Rated voltage U0/U (Um) 0.6/1 (1.2) kV

Test voltage 2.5 kV

AC test voltage (control cores) 2 kV

Nominal voltage U 1,000 V

In underground mining and tunnelling operations, power cables are exposed to extreme mechanical stress, frequent reeling, abrasion, torsion, moisture, and confined environments. Choosing the wrong cable can lead to premature failures, safety risks, and costly downtime.

Feichun PUR D2X11Y 1 kV Reeling Cable is specifically engineered for drilling rigs, scoops, and Load–Haul–Dump (LHD) machines, where cables must perform reliably under continuous dynamic movement.

What Is Feichun PUR D2X11Y 1 kV Reeling Cable Designed For?

Feichun PUR D2X11Y is a low-voltage (0.6/1 kV) flexible reeling cable designed for underground mining and tunnelling equipment subject to:

Continuous reeling and unreeling

High tensile and torsional stress

Severe abrasion during trailing operation

Confined spaces with strict fire and halogen-free requirements

It is commonly used as a power supply cable for:

Underground drilling machines

LHDs (Load–Haul–Dump machines)

Scoops and bolters

Mobile tunnelling equipment

How Is Feichun PUR D2X11Y Cable Structurally Designed for Reeling Applications?

The cable structure is optimized to balance flexibility, mechanical strength, and electrical stability.

What Type of Conductor Is Used and Why Does It Matter?

Finely stranded bare copper conductor (Class 5)

Conforms to DIN EN 60228 / IEC 60228 / VDE 0295

Why this matters:

Class 5 stranding ensures excellent flexibility, reducing conductor fatigue during repeated bending and reeling cycles.

Why Is XLPE Used as Core Insulation?

Each power core is insulated with XLPE (cross-linked polyethylene).

Key advantages of XLPE:

High thermal resistance (90 °C continuous)

Excellent dielectric strength

Superior ageing performance

Lower insulation losses compared to PVC

What Is the Purpose of Split Earth Conductors?

Feichun PUR D2X11Y uses a split earth conductor design, laid symmetrically around the main cores.

Benefits include:

Improved earth continuity during cable movement

Enhanced safety for mining personnel

Better mechanical balance during reeling

How Are the Cores Arranged to Withstand Dynamic Stress?

Three main power cores laid together

Split earth conductor and control cores placed in interstices

Very short lay length twisting to minimise internal stress

Core identification:

Main cores: brown, black, grey

Control cores: blue, white

Why Are Halogen-Free Inner and PUR Outer Sheaths Critical?

Inner sheath: Halogen-free polymer

Outer sheath: Flame-retardant polyurethane (PUR)

PUR advantages in mining:

Exceptional abrasion resistance

High cut and tear strength

Resistance to oils, grease, moisture, and chemicals

Long service life under harsh reeling conditions

What Are the Best Installation Practices for PUR D2X11Y Reeling Cables?

Use properly aligned reeling drums

Avoid exceeding the specified bending radius

Ensure even cable winding to prevent torsional stress

Inspect outer sheath regularly for mechanical damage

Avoid sharp edges and pinch points

Frequently Asked Questions (FAQ)

Is PUR D2X11Y suitable for continuous reeling operations?

Yes. It is specifically designed for frequent dynamic reeling with high torsional and tensile resistance.

Can this cable be used in wet underground environments?

Yes. It is suitable for up to 10 m water depth and has excellent moisture resistance.

Is PUR D2X11Y compliant with international standards?

Yes. It complies with DIN, VDE, IEC standards commonly accepted in South African mining projects.

Can it replace rubber reeling cables in existing systems?

In most cases, yes—provided drum dimensions and bending radius requirements are met.

Why Choose Feichun PUR D2X11Y for Mining Reeling Applications?

Feichun PUR D2X11Y combines:

Advanced PUR sheath technology

Optimised core design for reeling

High electrical and mechanical performance

Proven performance in South African mines

Call to Action (CTA)

Looking for a reliable, long-life reeling cable for drills or LHDs in underground mining?

👉 Contact Feichun Cable for:

Technical selection support

Customised cable configurations

Project references in South Africa

Fast delivery and export documentation

Feichun Mining Cable

Durable mining cables for tough environments and operations

Contact us:

© 2025. All rights reserved.