Anhui Feichun Special Cable Co.,Ltd Li.wang@feichuncables.com

(N)TSCGEWOEU LWL 6 - 35 KV MEDIUM VOLTAGE REELING CABLE WITH INTEGRATED FIBER-OPTICS

Feichun (N)TSCGEWOEU LWL 6 - 35 KV MEDIUM VOLTAGE REELING CABLE WITH INTEGRATED FIBER-OPTICS

Application:

For connection of large material handling machines such as excavators, dumpers, mobile crushers in opencast mines. Flexible MV reeling cable suitable for high mechanical stresses in conjunction with mono-spiral reels and cylindrical reels.

Structure:

1. Conductor Very finely stranded copper, bare (class FS) PE: Very finely stranded copper, bare, class FS

2. Inner semi-conducting layer Semi-conductive EPR

3. Core arrangement Three core design, with split earth conductor in three interstices; Optical element: six tubes, laid up around a central support element, each with one, two, three or four optical fibers

4. Core insulation EPR rubber, PROTOLON Special compound 3GI3

5. Outer semi-conducting layer Semi-conductive NBR easy-strip

6.Split Earth conductor

7. Optical fiber element

8. Inner sheath Rubber - Special compound 5GM3

9. Armoring / reinforcement Polyester Mesh tape

10. Outer sheath Polychloroprene (PCP) Special compound 5GM5

STANDARDS / APPROVALS:

DIN VDE 0250-813 General

EN 50525-2-21 Electrical parameters

DIN VDE 0207-21 Compound

DIN VDE 0298-3 Mechanical parameters

DIN EN 60811-404 / IEC 60811-404 Chemical behaviour

GOST -R/-K/-B Fire Certificate of Certifications / Approvals

Russian Federation

DIN EN 60332-1-2 / IEC 60332-1-2 Fire performance

THERMAL PARAMETERS:

Max. conductor temperature 90 °C

Max. conductor temperature at short circuit 250 °C

Ambient temperature fix installation (min) -40 °C

Ambient temperature fix installation (max) 80 °C

Ambient temperature flexible installation (min) -30 °C

Ambient temperature flexible installation (max) 80 °C

CHEMICAL PARAMETERS:

Flame retardant In accordance with EN/IEC 60332-1-2

Oil resistant Yes

Ozone resistance Yes

Resistant to UV Yes

Sea water resistance Yes

MECHANICAL PARAMETERS:

Torsional stress +/- 100 °/m

Permanent tensile strength (rule) 20 N/mm² static 25 N/mm² dynamic

Travel speed On rewinding: up to 100 m/min

Reeling operation: up to 120 m/min

Bending radius (rule)

Acc. to VDE 0298-3: 6 x D fixed installation

10 x D flexible operation

20 x D min distance with S-type directional changes

ELECTRICAL PARAMETERS:

Rated voltage U0/U (Um) in kV 3.6/6 (7.2) 6/10 (12) 8.7/15 (17.5) 12/20 (24) 14/25 (29) 18/30 (36) 20/35 (42)

Test voltage 11 kV 17 kV 24 kV 29 kV 36 kV 43 kV 50 kV

Nominal voltage U 6,000 V 10,000 V 15,000 V 20,000 V 25,000 V 30,000 V 35,000 V

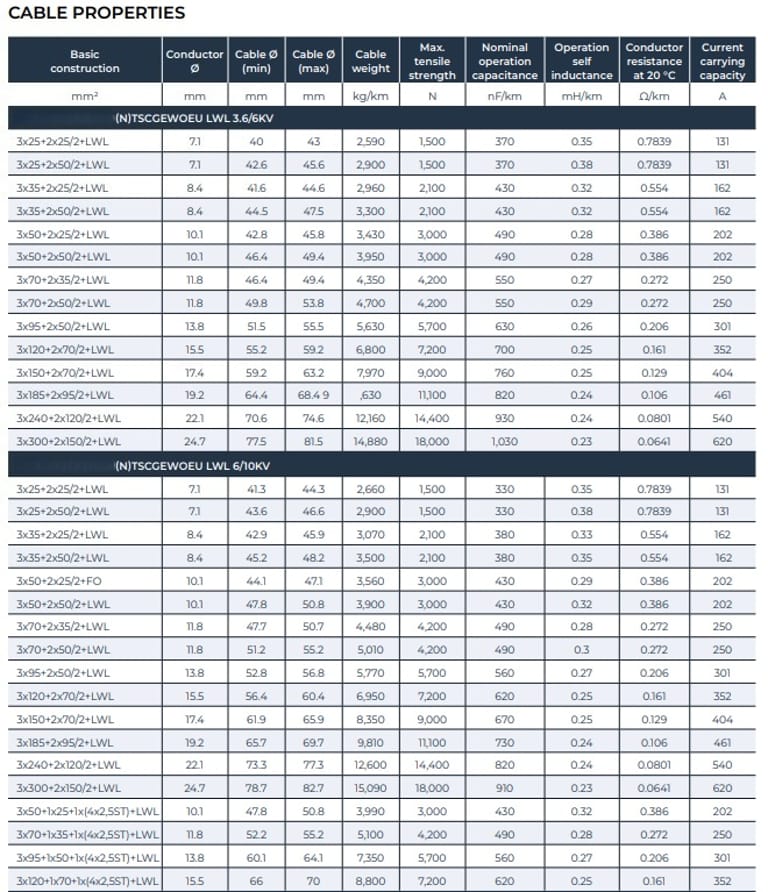

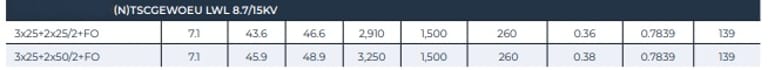

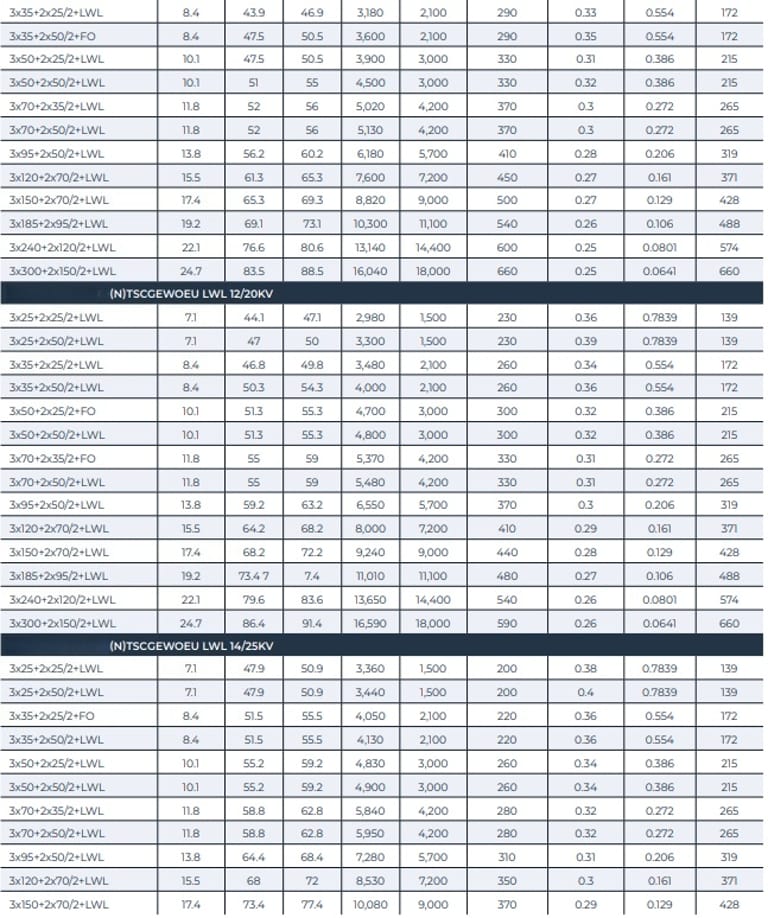

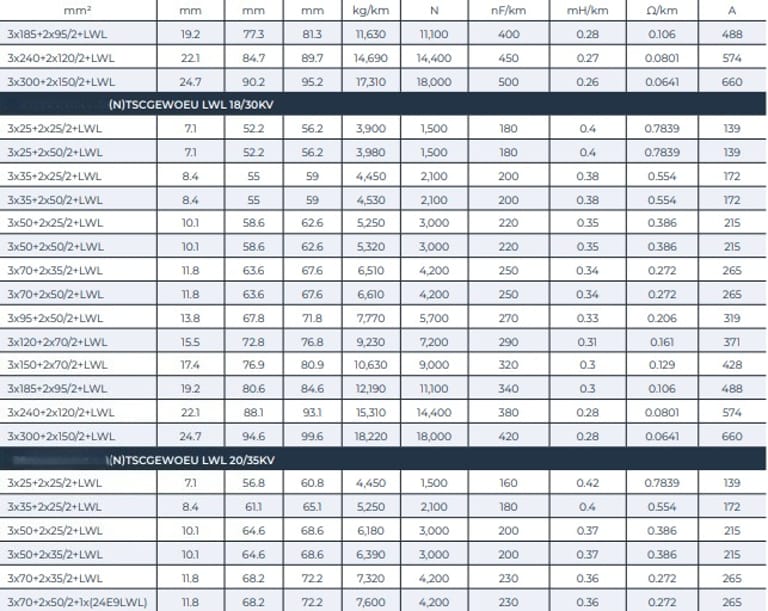

CABLE PROPERTIES:

How Does the (N)TSCGEWOEU LWL Compare to Other Medium Voltage Reeling Cables?

To illustrate its advantages, here’s a simplified comparison with typical MV reeling cables used in mining:

Feature | (N)TSCGEWOEU LWL | Standard MV Cable | Traditional MV Cable |

|---|---|---|---|

Max Rated Voltage | 35 kV | 20 kV | 15 kV |

Integrated Fiber-Optic | Yes | No | No |

Torsional Stress | ±100°/m | ±60°/m | ±50°/m |

UV & Ozone Resistance | Yes | Partial | No |

Flexible Temperature Range | -30°C to 80°C | -20°C to 70°C | 0°C to 60°C |

Current Carrying Capacity | Up to 660 A | Up to 350 A | Up to 200 A |

Application | Reeling on mono-spiral or cylindrical reels | Fixed or semi-flexible | Fixed only |

As shown, the (N)TSCGEWOEU LWL stands out for higher voltage ratings, flexibility, and integrated data communication, which are critical for modern mining operations.

What Are Typical Applications of the (N)TSCGEWOEU LWL Cable in South Africa?

In South African mining environments, this cable is widely used for:

Large Excavators and Draglines: Powering heavy machinery with dynamic movements on mono-spiral reels.

Mobile Crushers and Dumpers: High-current supply for equipment requiring frequent repositioning.

Material Handling Systems: Integrated fiber-optics enable remote monitoring and predictive maintenance.

Harsh Environments: Open-cast mines with exposure to UV, oil, seawater, and extreme temperatures.

Case Study: Open-Cast Platinum Mine, South Africa

A major platinum mine installed the 20/35 kV variant to supply power to mobile crushers. The integration of fiber-optics allowed the operation team to monitor real-time power load and equipment position. This minimized downtime and reduced maintenance costs by 18% annually.

What Are the Safety and Fire Performance Standards?

The (N)TSCGEWOEU LWL cable meets multiple international safety standards:

DIN VDE 0250-813 / EN 50525-2-21: General electrical standards

DIN EN 60811-404 / IEC 60811-404: Chemical resistance and material aging

DIN EN 60332-1-2 / IEC 60332-1-2: Flame retardant performance

GOST-R/-K/-B: Fire certificate approvals (Russia)

These standards ensure that the cable is safe for both operators and equipment, even in fire-prone mining environments.

What Are the Benefits of Integrated Fiber-Optics in MV Reeling Cables?

The integrated fiber-optics (LWL) provide several advantages:

Real-Time Monitoring: Transmission of electrical parameters from sensors to control rooms.

Predictive Maintenance: Early detection of overloads, wear, or mechanical stresses.

Data Communication: Connects SCADA systems, GPS, or telemetry for mobile mining equipment.

Cost Efficiency: Reduces downtime and avoids separate communication cabling.

By combining power and data in a single cable, mines simplify infrastructure while enhancing operational safety.

How Do I Choose the Right Cable Size for My Application?

Selecting the correct (N)TSCGEWOEU LWL variant depends on:

Rated voltage of equipment (6–35 kV)

Current carrying capacity requirements

Reel type (mono-spiral or cylindrical)

Distance between power source and equipment

Environmental conditions (UV, oil, seawater)

Example: A 15 kV mobile crusher requiring 250 A would benefit from a 3x70+2x50/2+LWL variant, providing sufficient current capacity and mechanical strength for high-speed reeling.

FAQ: Frequently Asked Questions About (N)TSCGEWOEU LWL Cables

Can I Use These Cables in Underground Mines?

Yes, but ensure ambient temperature and chemical resistance match underground conditions. Cable variants are rated for flexible operation from -30°C to 80°C.

How Do I Maintain the Cable on a Reeling System?

Regularly inspect for abrasion or mechanical damage.

Monitor torsion and bending radii during operation.

Keep reels clean and aligned to prevent uneven winding.

What Is the Lifespan of the Cable in Harsh Environments?

With proper installation and maintenance, the (N)TSCGEWOEU LWL cable can last 10–15 years, even in open-cast mines.

Can the Fiber-Optic Component Be Replaced?

No, the LWL fibers are embedded within the cable structure. For damaged fibers, the entire cable section must be replaced.

How Does It Compare to Conventional MV Cables?

Higher voltage rating (up to 35 kV)

Integrated fiber-optics for data communication

Superior mechanical and chemical resistance

Longer service life under repeated bending and reeling

Why Choose Feichun (N)TSCGEWOEU LWL Cable?

The Feichun (N)TSCGEWOEU LWL 6–35 kV medium voltage reeling cable is a highly flexible, mechanically robust, and technically advanced solution for South African mining operations. Its combination of high current capacity, integrated fiber-optics, chemical resistance, and thermal stability makes it suitable for:

Open-cast mining equipment (excavators, dumpers, mobile crushers)

Harsh environmental conditions

High-speed reeling systems

Remote monitoring and predictive maintenance

Investing in this cable ensures operational reliability, safety, and long-term efficiency for large-scale mining projects.

Feichun Mining Cable

Durable mining cables for tough environments and operations

Contact us:

© 2025. All rights reserved.