Anhui Feichun Kabel Khusus Co., Ltd

ICEA S-75-381 Type MP-GC Three-Conductor Mine Power Feeder Cable PVC Jacket 5kV

Applications :

These cables are designed for connections between units of mine distribution systems, suitable for direct burial in wet and dry locations.

Standards :

ICEA S-75-381/NEMA WC 58

ASTM B-8

CAN/CSA-C22.2 No.96 |  |

Construction :

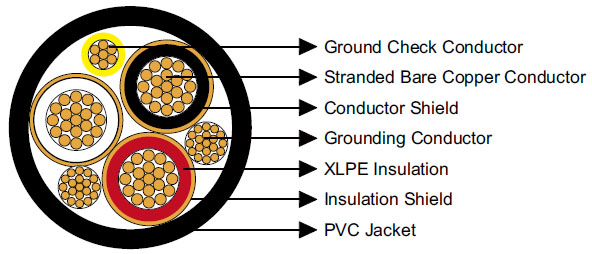

Conductor | Stranded annealed bare copper conductor. |

Conductor Shield | Conducting layer. |

Insulation | Cross-Linked Polyethylene (XLPE). |

Insulation Shield | Conducting layer + copper tape. |

Ground Check Conductor | Copper conductor with a yellow polypropylene insulation. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Polyvinyl Chloride (PVC), black. |

Options :

Other jacket materials such as CSP/PCP/NBR/CPE/TPU are available upon request.

Mechanical and Thermal Properties :

Minimum Bending Radius: 12×OD.

Maximum Conductor Operating Temperature: +90℃.

Dimensions and Weight :

Construction | No. of | Grounding | Ground | Nominal Insulation | Nominal Jacket | Nominal Overall | Nominal Weight | Ampacity | ||||

No. of cores | - | AWG/ | AWG/ | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×4 | 7 | 8 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.41 | 35.8 | 1224 | 1821 | 122 |

3×2 | 7 | 6 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.47 | 37.3 | 1653 | 2459 | 159 |

3×1 | 19 | 5 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.54 | 39.1 | 1950 | 2901 | 184 |

3×1/0 | 19 | 4 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.63 | 41.4 | 2200 | 3273 | 211 |

3×2/0 | 19 | 3 | 8 | 0.09 | 2.3 | 0.11 | 2.8 | 1.72 | 43.7 | 2721 | 4048 | 243 |

3×3/0 | 19 | 2 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 1.89 | 48.0 | 3170 | 4720 | 279 |

3×4/0 | 19 | 1 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 2.01 | 51.0 | 3845 | 5721 | 321 |

3×250 | 37 | 1/0 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 2.10 | 53.3 | 4321 | 6429 | 355 |

3×350 | 37 | 2/0 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 2.31 | 58.7 | 5652 | 8409 | 435 |

3×500 | 37 | 4/0 | 8 | 0.09 | 2.3 | 0.14 | 3.6 | 2.59 | 65.8 | 7721 | 11487 | 536 |

Ampacity-Based on a conductor temperature of 90℃ and an ambient air temperature of 40℃, per ICEA S-75-381.

In modern mining operations, reliable and durable power distribution is crucial. The ICEA S-75-381 Type MP-GC Three-Conductor Mine Power Feeder Cable with a PVC Jacket 5kV has emerged as a trusted solution for connecting units within mine distribution systems. From underground gold and platinum mines in South Africa to open-cast operations, this cable is engineered to deliver high performance under harsh conditions. But what sets it apart from other mine power feeder cables?

What Is the Structure of a Type MP-GC 5kV Mine Power Feeder Cable?

Understanding the internal structure is the first step to appreciating why this cable performs reliably in mining environments.

Conductor: The cable features a stranded annealed bare copper conductor, ensuring excellent conductivity and flexibility. Stranding enhances bending performance and mechanical durability, critical for mobile mining equipment.

Conductor Shield: A conducting layer surrounds each conductor, reducing electrical stress and enhancing safety.

Insulation: Made from Cross-Linked Polyethylene (XLPE), the insulation withstands high temperatures (up to 90°C) and offers chemical resistance in wet and dry environments.

Insulation Shield: The insulation shield includes a conducting layer with copper tape, which improves electrical performance and shields against electromagnetic interference.

Ground Check Conductor: An auxiliary copper conductor with yellow polypropylene insulation allows continuous grounding verification, crucial for underground operations.

Grounding Conductor: A tinned copper conductor ensures reliable earthing and corrosion resistance.

Jacket: The outer layer is Polyvinyl Chloride (PVC), black, providing abrasion resistance, UV protection, and mechanical robustness. Alternative jacket materials such as CSP, PCP, NBR, CPE, or TPU are available for specific operational requirements.

What Are the Typical Applications of Type MP-GC 5kV Cables?

These cables are widely used in mine distribution systems, connecting mobile equipment, transformers, and substations. They are suitable for:

Underground mining tunnels in South Africa (gold, platinum, and coal mines)

Direct burial in wet or dry locations

Mobile equipment such as continuous miners, longwall shearers, and shuttle cars

Emergency backup power and temporary installations

What Are Some Real-World South African Case Studies?

Case 1: Platinum Mine, Rustenburg

A Rustenburg platinum mine required a high-capacity feeder for a newly installed continuous miner. Type MP-GC 5kV was deployed for:

Underground direct burial

Connection between the main substation and mobile units

Operating under wet and abrasive tunnel conditions

The result: stable power delivery, reduced downtime, and extended cable life compared to older PVC/XLPE alternatives.

Case 2: Gold Mine, Gauteng

In a gold mine, frequent relocations of mobile equipment required a flexible, mechanically robust cable. Type MP-GC’s stranded copper conductors and PVC jacket enabled:

Quick re-routing of feeders

High resistance to mechanical wear and tear

Long-term safety compliance per ICEA S-75-381

What Are the Installation Best Practices for Type MP-GC 5kV?

Bending Radius: Maintain at least 12×OD to avoid conductor or insulation damage.

Direct Burial: Use a sand or fine soil layer to prevent abrasion.

Routing: Avoid sharp bends and areas prone to mechanical damage.

Temperature Considerations: Ensure ambient temperatures do not exceed 40°C, aligning with ampacity calculations.

Connections: Use properly rated lugs and connectors to maintain low resistance and high reliability.

Frequently Asked Questions (FAQ)

Can Type MP-GC 5kV Be Used in Wet Conditions?

Yes, the cable is suitable for direct burial in wet or dry locations. Its XLPE insulation and PVC jacket provide water and chemical resistance.

How Does the Ampacity of Type MP-GC Affect My Mining Equipment?

Ampacity determines how much current the cable can safely carry. Using a cable with insufficient ampacity may overheat and damage both the cable and equipment. Type MP-GC 5kV cables range from 122 A to 536 A, covering most underground mining applications.

What Makes PVC Jackets a Preferred Choice?

PVC jackets are abrasion-resistant, chemically stable, and UV-resistant, making them ideal for underground and surface mining conditions. They also provide cost-effective durability compared to specialty jackets like CPE or TPU.

How Does Type MP-GC Compare With SHD-GC in Flexibility?

Type MP-GC features stranded conductors and a 12×OD bending radius, which provides slightly better flexibility than SHD-GC, particularly for frequent relocations of mining equipment.

Can Type MP-GC Handle High-Load Mobile Equipment?

Absolutely. The stranded copper conductor design ensures mechanical strength and high ampacity, allowing safe use with continuous miners, longwall shearers, and other mobile machinery.

Why Choose Feichun Type MP-GC 5kV Cables for Your Mine?

Feichun’s Type MP-GC cables combine:

Mechanical flexibility for mobile operations

High ampacity suitable for demanding mining equipment

PVC jacket durability for long-term underground installation

Compliance with ICEA S-75-381, ASTM, and CSA standards

Installation Tips and Call-to-Action (CTA)

Always plan cable routes before installation to avoid unnecessary bends or stress.

Use sand bedding or protective conduits in high-wear areas.

Periodically inspect grounding and insulation for wear or damage.

Partner with authorized Feichun distributors for supply and technical support.

CTA: Explore Feichun Type MP-GC 5kV cables for your mine’s next power distribution upgrade. Ensure safety, compliance, and high performance by consulting with our certified mining electrical specialists today.

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: