Anhui Feichun Kabel Khusus Co., Ltd

ICEA S-75-381 Type MP-GC Three-Conductor Mine Power Feeder Cable CPE Jacket 25kV

Feichun ICEA S-75-381 Type MP-GC Three-Conductor Mine Power Feeder Cable CPE Jacket 25kV

Applications :

These cables are designed for connections between units of mine distribution systems, suitable for installed in duct, conduit or open air and for direct burial in wet and dry locations.

Standards :

ICEA S-75-381/NEMA WC 58

ASTM B-8

CAN/CSA-C22.2 No.96 |  |

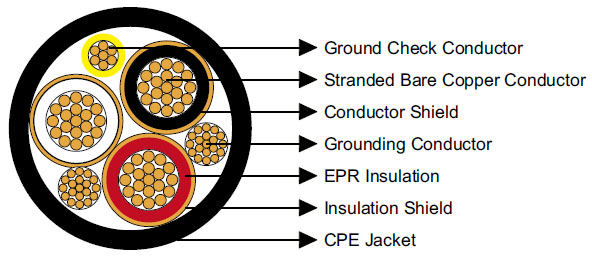

Construction :

Conductor | Stranded annealed bare copper conductor. |

Conductor Shield | Conducting layer. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Conducting layer + copper tape. |

Ground Check Conductor | Copper conductor with a yellow polypropylene insulation. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Chlorinated Polyethylene (CPE), black. |

Options :

Other jacket materials such as CSP/PCP/NBR/PVC/TPU are available upon request.

Mechanical and Thermal Properties :

Minimum Bending Radius: 12×OD.

Maximum Conductor Operating Temperature: +90℃.

Dimensions and Weight :

Construction | No. of | Grounding | Ground | Nominal Insulation | Nominal Jacket | Nominal Overall | Nominal Weight | Ampacity | ||||

No. of cores | - | AWG/ | AWG/ | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×1 | 19 | 5 | 8 | 0.260 | 6.4 | 0.14 | 3.6 | 2.37 | 60.2 | 3435 | 5112 | 187 |

3×1/0 | 19 | 4 | 8 | 0.260 | 6.4 | 0.14 | 3.6 | 2.45 | 62.2 | 3815 | 5677 | 218 |

3×2/0 | 19 | 3 | 8 | 0.260 | 6.4 | 0.14 | 3.6 | 2.54 | 64.5 | 4290 | 6384 | 249 |

3×3/0 | 19 | 2 | 8 | 0.260 | 6.4 | 0.14 | 3.6 | 2.65 | 67.3 | 4875 | 7255 | 286 |

3×4/0 | 19 | 1 | 8 | 0.260 | 6.4 | 0.14 | 3.6 | 2.81 | 71.4 | 5665 | 8430 | 327 |

3×250 | 37 | 1/0 | 8 | 0.260 | 6.4 | 0.17 | 4.3 | 2.97 | 75.4 | 6495 | 9666 | 360 |

3×350 | 37 | 2/0 | 8 | 0.260 | 6.4 | 0.17 | 4.3 | 3.18 | 80.8 | 7970 | 11860 | 438 |

3×500 | 37 | 4/0 | 8 | 0.260 | 6.4 | 0.17 | 4.3 | 3.45 | 87.6 | 10300 | 15328 | 536 |

In the dynamic mining industry, ensuring reliable power supply is critical for both safety and productivity. One cable that has garnered attention across mines is the Feichun ICEA S-75-381 Type MP-GC Three-Conductor Mine Power Feeder Cable with CPE Jacket 25kV. This high-performance cable is engineered to deliver durable, efficient power in harsh mining environments. But what makes it stand out compared to other mining cables? How does it meet the rigorous demands of modern underground and surface mining operations?

What Is the Structure of Type MP-GC 25kV Mine Power Feeder Cable?

The Type MP-GC 25kV cable features a robust, multi-layered construction designed for mechanical resilience and electrical performance:

Conductor: Stranded, annealed bare copper provides excellent conductivity while allowing flexibility for installation and bending around tight corners in tunnels or ducting systems.

Conductor Shield: A conducting layer ensures uniform electrical stress distribution, reducing the risk of insulation breakdown.

Insulation: Made of Ethylene Propylene Rubber (EPR), the insulation is thermally stable and resistant to moisture and chemical exposure.

Insulation Shield: A combination of a conducting layer and copper tape improves grounding continuity and enhances protection against electrical faults.

Ground Check Conductor: A copper conductor coated in yellow polypropylene insulation allows for monitoring of grounding integrity.

Grounding Conductor: Tinned copper provides corrosion-resistant grounding, essential in wet mining environments.

Jacket: Chlorinated Polyethylene (CPE) in black provides abrasion resistance, chemical resistance, and protection against mechanical wear. Optional jackets like CSP, PCP, NBR, PVC, or TPU can be supplied based on specific environmental conditions.

This multi-layer construction balances flexibility, mechanical strength, and electrical performance, making it suitable for both underground tunnels and surface installations.

What Are the Common Applications of Type MP-GC 25kV Cables in Mining?

Type MP-GC 25kV cables are widely used in South African mining operations, particularly in gold, platinum, and coal mines. Applications include:

Mine Distribution Systems: Connecting high-power units within underground and surface distribution networks.

Mobile Equipment: Powering longwall shearers, continuous miners, shuttle cars, and conveyor drives.

Surface Installations: Ideal for direct burial, open-air, or ducted applications where mechanical protection is needed.

Wet or Dry Locations: Suitable for tunnels and open pits with exposure to water or chemicals.

How Should Type MP-GC 25kV Cables Be Installed Safely?

Installation is critical to ensure long-term performance. Best practices include:

Follow Bending Radius: Always maintain a minimum bending radius of 12×OD to avoid conductor or insulation damage.

Avoid Abrasion: Use cable trays, ducting, or sheaves to prevent rubbing against sharp edges.

Monitor Ground Check Conductor: Ensure the ground check conductor is intact and connected to verify grounding continuity.

Environmental Considerations: For high-temperature areas, avoid prolonged exposure above +90°C. For wet environments, ensure proper drainage to minimize standing water.

Jacket Selection: If chemical exposure or extreme abrasion is expected, consider alternative jackets such as CSP, NBR, or TPU.

Frequently Asked Questions (FAQ) About Type MP-GC 25kV Cables

What is the difference between Type MP-GC and Type SHD-GC cables?

Type MP-GC is optimized for flexibility and higher ampacity, suitable for mobile equipment, whereas Type SHD-GC focuses on mechanical protection in fixed installations. MP-GC cables are easier to route through tight bends in underground tunnels.

Can Type MP-GC cables be used outdoors?

Yes. With a CPE jacket, these cables resist UV, moisture, and chemical exposure, making them suitable for both underground and surface installations, including direct burial.

Are there alternatives to CPE jackets?

Yes, depending on application requirements, jackets such as CSP, PCP, NBR, PVC, or TPU are available to resist specific environmental hazards like oil, solvents, or extreme wear.

How do I choose the right conductor size?

Select conductor size based on:

Required current (ampacity)

Installation length (to minimize voltage drop)

Mechanical stresses

Future expansion plans

For example, high-capacity continuous miners typically use 3×350 kcmil or 3×500 kcmil, while smaller feeders may use 3×1/0 or 3×2/0 AWG.

For mining engineers and procurement managers looking to enhance power reliability and operational safety, the Feichun Type MP-GC 25kV Mine Power Feeder Cable is a trusted choice. Contact authorized distributors to explore available sizes, jacket options, and installation support. Ensure your mining operations remain safe, efficient, and compliant with international standards.

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: