Anhui Feichun Kabel Khusus Co., Ltd

Feichun Type SHD-CGC Three-Conductor Round Portable Power Cable 2kV Heavy Duty Cable Designed for Applications Such as Longwall Shearers, Continuous Miners

Feichun Type SHD-CGC Three-Conductor Round Portable Power Cable 2kV

Applications :

These heavy duty cables are designed for applications such as longwall shearers, continuous miners, loaders,drills, conveyors, pumps, and other mobile equipment requiring grounding conductors, where a ground check conductor, and metallic shielding are required.

Standards :

ICEA S-75-381/NEMA WC 58

ASTM B 172

ASTM B 33

CAN/CSA C22.2 No. 96 |  |

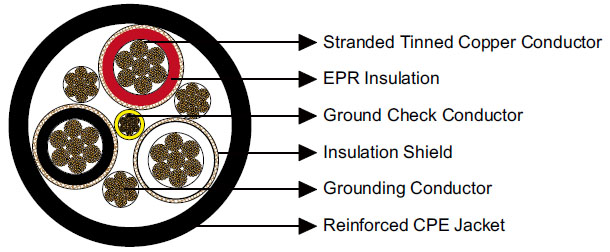

Construction :

Conductor | Stranded annealed tinned copper conductor. |

Insulation | Ethylene Propylene Rubber (EPR). |

Insulation Shield | Tinned copper/textile braid. |

Ground Check Conductor | Tinned copper with a yellow insulation, located in the center of the cable. |

Grounding Conductor | Tinned copper conductor. |

Jacket | Reinforced extra-heavy-duty Chlorinated Polyethylene (CPE), black. |

Options :

Other jacket materials such as CSP/PCP/NBR/PVC are available upon request.

Two-layer jacket with reinforcing fibre between the two layers can be offered as an option.

Mechanical and Thermal Properties :

Minimum Bending Radius: 6×OD.

Maximum Conductor Operating Temperature: +90℃.

Dimensions and Weight :

Construction | No. of | Grounding | Ground | Nominal Insulation | Nominal Jacket | Nominal Overall | Nominal Weight | Ampacity | ||||

No. of cores | - | AWG/ | AWG/ | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×2/0 | 342 | 5 | 16 | 0.08 | 2.0 | 0.205 | 5.2 | 2.09 | 53.1 | 3400 | 5059 | 243 |

3×3/0 | 418 | 4 | 16 | 0.08 | 2.0 | 0.205 | 5.2 | 2.21 | 56.1 | 3934 | 5853 | 279 |

3×4/0 | 532 | 3 | 16 | 0.08 | 2.0 | 0.220 | 5.6 | 2.36 | 59.9 | 4860 | 7231 | 321 |

3×350 | 888 | 1 | 16 | 0.95 | 2.4 | 0.250 | 6.3 | 2.81 | 71.4 | 7400 | 11010 | 435 |

Ampacity-Based on a conductor temperature of 90℃ and an ambient air temperature of 40℃, per ICEA S-75-381.

What Does “SHD-CGC” Mean in a 2kV Portable Mining Cable?

SHD-CGC is a designation used in North American–style mining cables that reflects both mechanical duty level and safety features:

SHD – Super Heavy Duty, designed for severe mechanical stress

C – Ground Check Conductor included

G – Grounding Conductor included

C – Metallic Shielding present

In practical terms, an SHD-CGC cable is built for high-power mobile mining machines that require:

Continuous grounding

Ground-check monitoring

Shielded insulation for enhanced safety

Maximum resistance to crushing, dragging, and abrasion

Why Is a Ground Check Conductor Critical in Underground Mining?

A ground check conductor, centrally located in the Feichun SHD-CGC cable, plays a vital role in mine safety systems.

It allows ground-monitoring relays to:

Detect loss of grounding continuity

Automatically shut down power if grounding fails

Prevent shock hazards to operators

In South African coal and platinum mines, ground-check systems are widely mandated for continuous miners, loaders, and longwall equipment, making SHD-CGC cables a preferred solution.

What Are the Key Electrical and Mechanical Specifications?

What Is the Rated Voltage and Temperature?

Voltage rating: 2kV

Maximum conductor temperature: +90 °C

Minimum bending radius: 6 × overall diameter

This makes the cable suitable for tight underground installations and frequent movement.

What Are the Ampacity Ratings?

Ampacity is based on:

90 °C conductor temperature

40 °C ambient air

ICEA S-75-381 methodology

Construction | Overall Diameter (mm) | Weight (kg/km) | Ampacity (A) |

|---|---|---|---|

3 × 2/0 AWG | 53.1 | 5059 | 243 |

3 × 3/0 AWG | 56.1 | 5853 | 279 |

3 × 4/0 AWG | 59.9 | 7231 | 321 |

3 × 350 kcmil | 71.4 | 11010 | 435 |

Where Is the SHD-CGC 2kV Cable Typically Used?

What Mining Equipment Requires SHD-CGC Cables?

Longwall shearers

Continuous miners

Load-haul-dump (LHD) machines

Roof bolters

Mobile drills

High-capacity conveyors

Pumps and auxiliary mobile equipment

These machines demand continuous power under constant movement, making SHD-CGC ideal.

What Are the Recommended Installation Practices?

How Should SHD-CGC Cables Be Installed Correctly?

Maintain minimum bending radius during routing

Avoid twisting during deployment

Use compatible mining-rated connectors

Protect cable from sharp edges at entry points

Perform ground-check continuity testing before energizing

Proper installation significantly extends service life.

Frequently Asked Questions (FAQ)

Is SHD-CGC Suitable for Surface Mining?

Yes. While designed for underground use, it is also suitable for harsh surface mining environments with high mechanical stress.

Can SHD-CGC Replace SHD-GC Directly?

Yes, but SHD-CGC offers additional shielding and may require connector compatibility checks.

Is This Cable Compliant with International Standards?

Yes. It complies with:

ICEA S-75-381 / NEMA WC 58

ASTM B172 / B33

CAN/CSA C22.2 No. 96

Can Jacket Materials Be Customized?

Yes. Feichun offers custom jacket systems, including dual-layer reinforced designs for extreme conditions.

Why Choose Feichun for SHD-CGC Mining Cables?

Feichun combines:

Proven mining cable design

Compliance with international standards

Custom engineering capability

Experience serving African mining projects

If you are selecting or upgrading 2kV portable power cables for continuous miners or mobile mining equipment, Feichun SHD-CGC offers a reliable, safety-focused solution.

👉 Contact Feichun’s technical team for:

Cable sizing recommendations

Application-specific customization

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: