Anhui Feichun Kabel Khusus Co., Ltd

Feichun Type G Three-Conductor Round Portable Power Cable 2kV For Use with Mobile Mining Equipment

Feichun Type G Three-Conductor Round Portable Power Cable 2kV For Use with Mobile Mining Equipment

Application:

These cables are designed for use with mobile mining equipment, such as continuous miners, cutting or loading machines, conveyors, drills or pumps.

Standards:

ICEA S-75-381/NEMA WC 58

ASTM B 172

ASTM B 33

CAN/CSA C22.2 No. 96

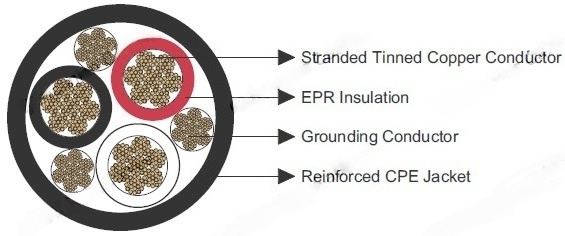

Construction:

Conductors Stranded annealed tinned copper conductor.

Insulation Ethylene Propylene Rubber (EPR).

Grounding Conductor Tinned copper conductor with an optional green outer covering.

Jacket Reinforced heavy-duty/extra-heavy-duty Chlorinated Polyethylene (CPE), black. (Cables having a nominal outside diameter of more than 2.0 inches require extra-heavy-duty jackets.)

Options:

Other jacket materials such as CSP/PCP/NBR/PVC are available upon request.

Two-layer jacket with reinforcing fibre between the two layers can be offered as an option.

Mechanical and Thermal Properties:

Minimum Bending Radius 6×OD

Maximum Conductor Operating Temperature +90℃

Dimensions and Weight:

Construction | No. of Strands | Grounding Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter Height×Width | Nominal Weight | Ampacity | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

No. of cores × AWG/kcmil | - | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

3×8 | 133 | 10 | 0.06 | 1.5 | 0.125 | 3.2 | 0.91 | 23.1 | 590 | 878 | 59 |

3×6 | 168 | 10 | 0.06 | 1.5 | 0.140 | 3.6 | 1.01 | 25.7 | 760 | 1131 | 79 |

3×4 | 259 | 8 | 0.06 | 1.5 | 0.155 | 3.9 | 1.17 | 29.7 | 1070 | 1592 | 104 |

3×3 | 329 | 8 | 0.06 | 1.5 | 0.155 | 3.9 | 1.24 | 31.5 | 1280 | 1904 | 120 |

3×2 | 259 | 8 | 0.06 | 1.5 | 0.155 | 3.9 | 1.34 | 34.0 | 1530 | 2276 | 138 |

3×1 | 329 | 7 | 0.08 | 2.0 | 0.170 | 4.3 | 1.51 | 38.4 | 1890 | 2812 | 161 |

3×1/0 | 259 | 6 | 0.08 | 2.0 | 0.170 | 4.3 | 1.65 | 41.9 | 2320 | 3452 | 186 |

3×2/0 | 329 | 5 | 0.08 | 2.0 | 0.190 | 4.8 | 1.75 | 44.5 | 2700 | 4017 | 215 |

3×3/0 | 413 | 4 | 0.08 | 2.0 | 0.190 | 4.8 | 1.89 | 48.0 | 3270 | 4865 | 249 |

3×4/0 | 532 | 3 | 0.08 | 2.0 | 0.205 | 5.2 | 2.04 | 51.8 | 3970 | 5907 | 287 |

3×250 | 608 | 2 | 0.095 | 2.4 | 0.220 | 5.6 | 2.39 | 60.7 | 5080 | 7558 | 320 |

3×300 | 741 | 1 | 0.095 | 2.4 | 0.235 | 6.0 | 2.56 | 65.0 | 6080 | 9046 | 357 |

3×350 | 855 | 1 | 0.095 | 2.4 | 0.235 | 6.0 | 2.68 | 68.1 | 7140 | 10623 | 394 |

3×400 | 988 | 1/0 | 0.095 | 2.4 | 0.250 | 6.4 | 2.82 | 71.6 | 7780 | 11575 | 430 |

3×500 | 1221 | 2/0 | 0.095 | 2.4 | 0.250 | 6.4 | 3.03 | 77.0 | 9065 | 13487 | 487 |

In modern mining operations, reliable and flexible power supply is critical to ensure safety, efficiency, and continuous operation. The Feichun Type G Three-Conductor Round Portable Power Cable 2kV has emerged as a preferred choice for mobile mining equipment, including continuous miners, loading machines, conveyors, drills, and pumps. But what makes this cable stand out, and why is it widely adopted in South African mines?

What Standards Does Feichun Type G Cable Comply With?

Feichun Type G cables adhere to internationally recognized standards, ensuring reliability and safety:

ICEA S-75-381/NEMA WC 58 – Defines power cable construction for mobile and portable equipment.

ASTM B 172 & ASTM B 33 – Standard specifications for copper conductors and copper wire.

CAN/CSA C22.2 No. 96 – Canadian standard for flexible power cables used with mobile equipment.

Compliance with these standards guarantees that the cables meet rigorous electrical, thermal, and mechanical performance requirements, making them ideal for heavy-duty mining operations.

Where Are Feichun Type G Cables Used in Mining Operations?

Feichun Type G cables are widely deployed in mobile mining equipment scenarios, including:

Continuous miners and cutting machines – Supplying power to high-performance mining equipment operating in tunnels.

Loading and hauling machines (LHDs) – Ensuring continuous operation without downtime.

Conveyor systems – Providing reliable energy to transport ore and waste materials.

Drills and pumps – Supporting water removal and drilling operations in underground mining.

How Do Feichun Type G Cables Compare With Other Portable Power Cables?

When choosing a cable for mobile mining equipment, several factors are considered: flexibility, ampacity, insulation material, and jacket durability. Below is a simplified comparison:

Feature | Feichun Type G | Standard Rubber Cable | PVC Portable Cable |

|---|---|---|---|

Conductor Type | Stranded tinned copper | Stranded copper | Solid or stranded copper |

Insulation Material | EPR | Rubber | PVC |

Max Temp (°C) | +90 | +75 | +70 |

Jacket Type | CPE (heavy-duty) | Rubber | PVC |

Minimum Bending Radius | 6×OD | 8×OD | 10×OD |

Ideal For Mobile Equipment | Excellent | Moderate | Limited |

As the table demonstrates, Feichun Type G provides superior flexibility, thermal tolerance, and mechanical protection, making it ideal for demanding mining environments.

Frequently Asked Questions (FAQ)

Can Feichun Type G cable be customized?

Yes. The cable can be ordered with alternative jacket materials such as CSP, PCP, NBR, or PVC. A two-layer reinforced jacket is also available for operations requiring extreme mechanical protection.

How do I select the right conductor size?

Select a conductor size based on ampacity requirements and equipment load. For instance, 3×4 AWG is sufficient for medium-load drills, while 3×500 AWG supports high-power continuous miners. Always check voltage drop and load calculations.

How does it compare with Type W or Type NTSCGEWOEU cables?

Type G excels in flexibility and portability for mobile equipment, while Type W is primarily single-conductor and Type NTSCGEWOEU is medium-voltage for semi-flexible installation. Type G is more suitable for frequent movement and abrasion-resistant environments.

What maintenance practices are recommended?

Visual inspection for cuts, abrasion, or deformation

Regular cleaning to remove dust, mud, and residues

Avoiding excessive pulling or dragging

Ensuring grounding connections are secure

What Are the Benefits of Using Feichun Type G Cables?

High flexibility: Easy to handle in mobile mining operations.

Durable construction: Resistant to abrasion, chemicals, and mechanical stress.

Thermal tolerance: Operates safely at temperatures up to +90°C.

Compliance with standards: ICEA, ASTM, and CSA certified.

Customizable options: Jackets, insulation, and reinforcement tailored to operational needs.

Upgrade Your Mining Equipment Power Supply Today

For mining operators and beyond, choosing the right portable power cable can directly impact productivity and safety. The Feichun Type G Three-Conductor Round Portable Power Cable 2kV offers flexibility, durability, and compliance, making it the ideal choice for mobile mining equipment.

Contact Feichun distributors today to select the optimal cable size for your operation and explore custom options tailored to your mine's needs.

Email: Li.wang@feichuncables.com

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: