Anhui Feichun Kabel Khusus Co., Ltd

AS/NZS 2802 Type 455 3.3-11 kV Mining Cable

Cable description:

Class 1 semiconductive screened cable for general use.

Application:

3.3/3.3 kV to 11/11 kV reeling cables for use with drag-lines, shovels, excavators, wharf cranes, and materials handling equipment. The cable is similar to Type 450 cables, without a composite insulation screen. This cable is suitable for slow reeling and trailing applications.

Approvals: AS/NZS 2802

Behaviour in flame and fire: Fire retardant

Temperature range:

Maximum operating temperature: +90°C

Minimum operating temperature: -25 °C

Flexibility: Flexible

Resistance to:

Chemical exposure: Very good/Frequent

Mechanical impact: Heavy

Water exposure: Immersion/Temporary coverage

Solar radiation and

weather exposure: Suitable for direct exposure

Cable design:

Semiconductive elastomer screened power cores with two earth and one pilot core.

Core: Metal: tinned copper, three core plus two earths and one pilot.

Insulation: EPR (XR-EP-90) semiconductive elastomer screened with numbered cores.

Earth: Two semiconductive elastomer covered, disposed in the cable interstices.

Pilot: One, elastomer covered, disposed in the cable interstices.

Sheath: Extra heavy duty XHD-85-PCP, incorporating a polyaramid Kevlar® braid reinforcement.

Installation conditions:

In free air

Mobile equipment

How Does Type 455 Cable Compare With Other Feichun Mining Cables?

To make an informed choice, understanding the differences between Type 455 and similar cables is critical. Below is a quick comparison:

Feature | Type 450 | Type 455 | Type 461 |

|---|---|---|---|

Voltage range | 3.3–11 kV | 3.3–11 kV | 6.6–22 kV |

Insulation screen | Composite | Semiconductive elastomer | Semiconductive elastomer |

Sheath | XHD-85-PCP | XHD-85-PCP + Kevlar® | XHD-85-PCP + Kevlar® |

Ideal use | Trailing & reeling | Slow reeling, trailing | High-voltage reeling & trailing |

Fire resistance | Fire-retardant | Fire-retardant | Fire-retardant |

Flexibility | Medium | High | Medium |

Key takeaway: Type 455 is best suited for slow reeling applications where high mechanical strength, flexibility, and safety under heavy-duty operation are required.

Where Is Feichun Type 455 Cable Used in Mining Applications?

The Type 455 cable is widely adopted in open-cut mining and port operations due to its mechanical and electrical resilience. Typical applications include:

Drag-lines and Shovels: Reeling cables for heavy excavation machinery.

Excavators: Flexible power supply for moving equipment.

Wharf Cranes and Materials Handling: Cables that withstand repetitive motion and mechanical stress.

What Are the Advantages of Type 455 Mining Cable?

Type 455 stands out due to several advantages:

Mechanical Strength: Kevlar® reinforcement protects against abrasion and heavy impact.

Electrical Reliability: EPR insulation maintains performance under high temperatures and variable loads.

Chemical and Water Resistance: Suitable for harsh mining environments with frequent chemical exposure.

Flexibility: Ideal for slow reeling and trailing applications.

Fire Safety: Fire-retardant properties enhance workplace safety.

Frequently Asked Questions (FAQ)

Can Type 455 Cable Be Used in Wet or Immersed Conditions?

Yes. Type 455 cables are designed for temporary immersion and direct water exposure, making them suitable for port cranes and wet mining conditions.

How Does Type 455 Differ From Type 450?

Screening: Type 450 uses composite insulation screening; Type 455 uses a semiconductive elastomer screen.

Flexibility: Type 455 is more flexible, ideal for slow reeling.

Application: Both are trailing cables, but Type 455 is preferred for mobile equipment requiring enhanced durability.

What Are the Recommended Voltage Ratings for Type 455?

Operates from 3.3 kV to 11 kV, covering most heavy-duty mining equipment in South Africa.

Can Type 455 Handle High Temperatures?

Yes. Maximum operating temperature is +90°C, with insulation and sheathing materials resistant to heat and fire.

Is Type 455 Fire Retardant?

Absolutely. The cable meets AS/NZS 2802 fire-retardant requirements, ensuring compliance with South African mining safety regulations.

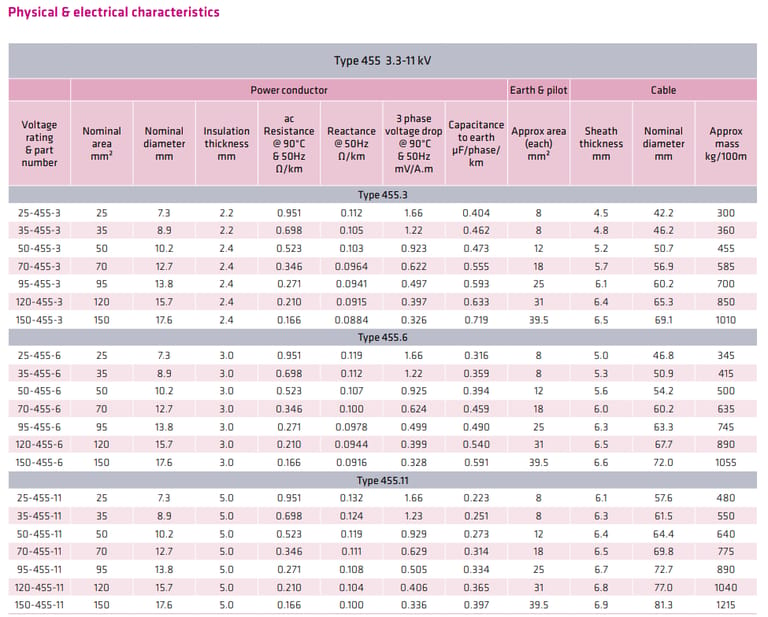

How to Compare Type 455 Sizes for Your Application?

Conductor Size | Max Current (A) | Voltage Drop (mV/A.m) | Mass (kg/100m) | Recommended Use |

|---|---|---|---|---|

25 mm² | 95–100 | 1.66 | 300–480 | Small machinery, auxiliary circuits |

50 mm² | 125–150 | 0.923 | 455–640 | Medium shovels, light drag-lines |

95 mm² | 180–200 | 0.497 | 700–890 | Heavy-duty excavators and cranes |

150 mm² | 250–280 | 0.326 | 1010–1215 | Large drag-lines, port cranes |

This table allows engineers to match cable size to equipment load, optimizing efficiency and longevity.

Why Should Mining Companies Choose Feichun Type 455 Cable?

Choosing the right mining cable is not just a technical decision — it impacts safety, reliability, and operational efficiency. The Type 455 cable provides:

Durability under mechanical, chemical, and environmental stress

Flexibility for slow reeling and trailing applications

Fire retardance for safety compliance

Proven performance in South African mines and industrial operations

Investing in high-quality cables like the Type 455 reduces downtime, minimizes maintenance costs, and ensures safe operation of mobile mining equipment.

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: