Anhui Feichun Kabel Khusus Co., Ltd

AS/NZS 2802 Type 451 3.3-33 kV

Feichun AS/NZS 2802 Type 451 3.3-33 kV

Cable description:

Class 1 composite screened cable for general use.

Application:

3.3/3.3 kV to 33/33 kV reeling cables similar to Type 450 cables but with reduced pilot size, for use with drag-lines, shovels, excavators, wharf cranes, and materials handling equipment. This cable is suitable for slow reeling and trailing applications.

Approvals:

AS/NZS 2802

Behaviour in flame and fire:

Fire retardant

Temperature range:

Maximum operating temperature: +90°C

Minimum operating temperature: -25 °C

Flexibility: Flexible

Resistance to:

Chemical exposure: Very good/Frequent

Mechanical impact: Heavy

Water exposure: Immersion/Temporary coverage

Solar radiation and

weather exposure: Suitable for direct exposure

Cable design:

Composite screened power cores with two earth and one pilot core.

Core: Metal: tinned copper, three core plus two earths and one pilot.

Semiconductive barrier taped and elastomer screened.

Insulation: EPR (XR-EP-90) semiconductive elastomer screened.

Screen: Composite tinned annealed copper wire and polyester yarn screen, under a semiconductive tape.

Core colours: red, white, blue, braid tracers.

Earth: Two semiconductive elastomer covered, disposed in the cable interstices.

Pilot: One, elastomer covered, disposed in the cable interstices.

Sheath: Extra heavy duty XHD-85-PCP, incorporating a polyaramid Kevlar® braid reinforcement. Installation conditions In free air Mobile equipment

Installation conditions:

In free air

Mobile equipment

What Is the Feichun AS/NZS Type 451 Mining Cable?

The Feichun AS/NZS Type 451 is a Class 1 composite screened cable designed for general mining use. It is a reeling and trailing cable suitable for slow-moving equipment, such as draglines, shovels, excavators, wharf cranes, and materials handling machinery.

Compared to its close relative, the Type 450 cable, the Type 451 has a reduced pilot size, which optimizes flexibility while maintaining safety and performance in heavy-duty mining operations.

Key highlights include:

Voltage rating: 3.3/3.3 kV to 33/33 kV

Flexibility: Suitable for trailing and slow reeling

Temperature range: -25°C to +90°C

Fire behavior: Fire-retardant and suitable for harsh mining conditions

Resistance: Excellent chemical resistance, heavy mechanical impact tolerance, temporary water immersion, and solar/weather exposure suitability

Where Can the Type 451 Mining Cable Be Applied?

The Type 451 is versatile and can be used in multiple mining scenarios:

Which Mining Equipment Is Compatible?

Draglines and Excavators: Ensures reliable power transmission even under continuous motion

Shovels: Maintains safety and performance in heavy-duty material handling

Wharf Cranes: Durable enough for coastal and port-based mining operations

Materials Handling Equipment: Suitable for slow reeling and trailing applications

How Does Type 451 Compare to Other Mining Cables?

Comparison Table: Type 450 vs Type 451

Feature | Type 450 | Type 451 |

|---|---|---|

Pilot Size | Standard | Reduced for flexibility |

Voltage Range | 3.3–33 kV | 3.3–33 kV |

Mechanical Reinforcement | XHD sheath | XHD-85-PCP + Kevlar® braid |

Best For | Slow reeling | Slow reeling + trailing, mobile equipment |

Typical Applications | Draglines, shovels | Draglines, shovels, excavators, cranes |

Summary: Type 451 offers the same power capabilities as Type 450 but with enhanced flexibility and reduced pilot size, making it ideal for mobile or trailing applications.

How Should the Type 451 Cable Be Installed?

Proper installation ensures maximum cable longevity and safety.

What Are Installation Recommendations?

For free-air installation: Ensure minimum bending radius is maintained according to voltage and conductor size

For mobile equipment: Avoid sharp bends; maintain consistent reeling and trailing tension

Environmental precautions: Keep the cable away from corrosive chemicals, extreme heat sources, and mechanical pinch points

Routine inspections: Check sheath integrity, pilot continuity, and screen bonding before full deployment

Pro Tip: Using cable rollers and protective sheaths in high-wear zones significantly increases service life.

Frequently Asked Questions (FAQ) About Type 451 Mining Cable

Can Type 451 Cables Be Used in Underground Mines?

Yes. While originally designed for open-cut mines, the Type 451’s fire-retardant and flexible design make it suitable for underground slow-reeling operations with moderate mechanical stress.

What Is the Maximum Operating Temperature?

The Type 451 operates safely up to +90°C. It can handle extreme South African summer heat, ensuring consistent power transmission.

How Resistant Is It to Mechanical Impact?

The Kevlar® reinforced XHD sheath provides heavy mechanical impact resistance. It can endure dragging over rough surfaces and minor collisions without damage.

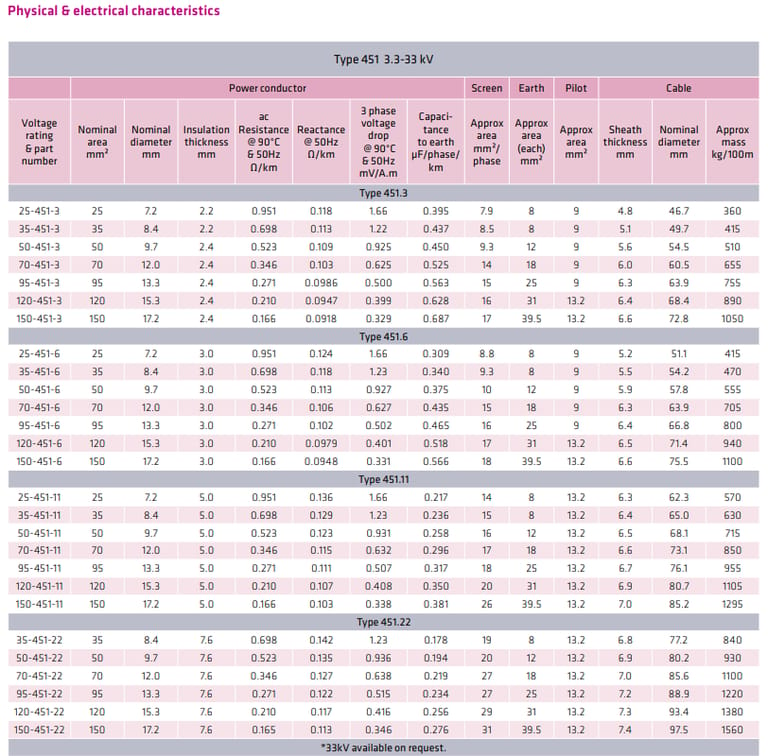

What Are the Differences Between Voltage Variants?

Higher voltage variants (11–33 kV) have:

Thicker insulation for dielectric strength

Heavier sheaths for mechanical protection

Slightly higher mass per 100 m

These design adjustments maintain electrical performance and safety at higher voltages.

Installation Tips for Maximum Longevity

Avoid sharp bends below recommended bending radius

Use proper supports to minimize cable drag on sharp edges

Keep the cable clean and free from chemical spills

Test pilot continuity regularly for operational safety

Document cable deployment to anticipate wear patterns

Why South African Mining Companies Choose Type 451

South African mining operations often demand long-distance, high-voltage power for mobile equipment. The Type 451 is favored because:

Durable in harsh environments: Chemical, mechanical, and thermal resistance

Flexible and adaptable: Ideal for slow reeling and trailing applications

Safety-certified: Meets AS/NZS 2802 standards

Proven in real cases: Increased uptime in platinum and gold belt mines

If you are responsible for mining operations, equipment maintenance, or industrial power distribution, considering Feichun AS/NZS Type 451 mining cables can significantly enhance reliability, safety, and operational efficiency. Contact your Feichun today to discuss custom cable lengths, voltage ratings, and installation support tailored to your mining environment.

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: