Anhui Feichun Kabel Khusus Co., Ltd

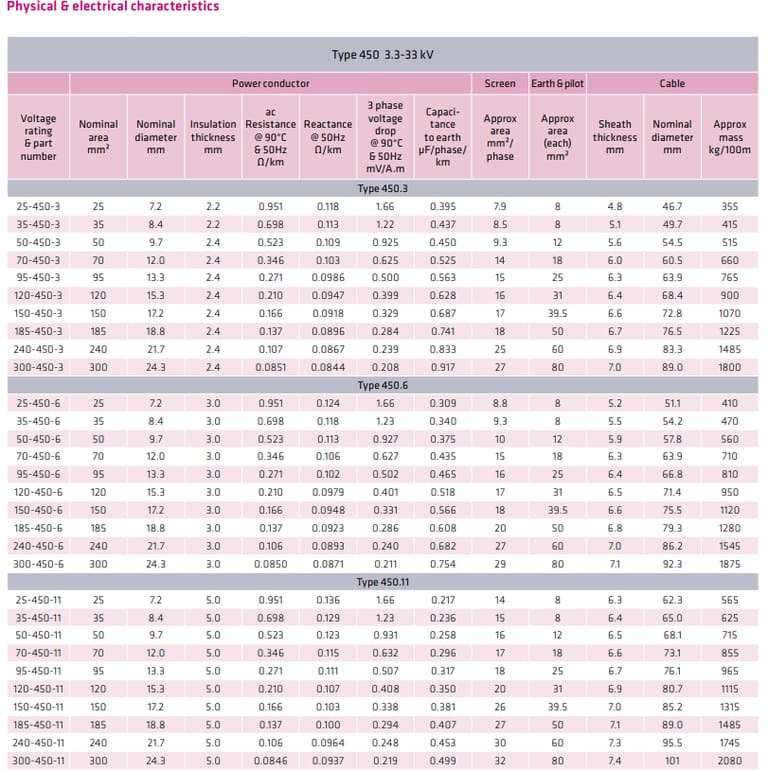

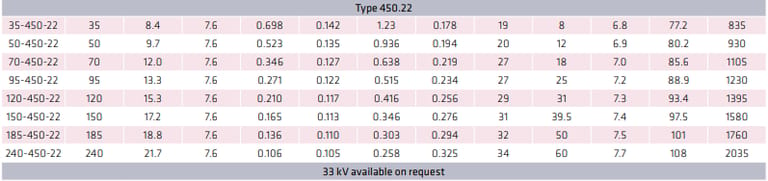

AS/NZS 2802 Type 450 3.3-33 kV Mining Cable

Feichun AS/NZS 2802 Type 450 3.3-33 kV Mining Cable

Cable description:

Class 1 composite screened cable for general use.

Application:

3.3/3.3 kV to 33/33 kV reeling cables for use with drag-lines, shovels, excavators, wharf cranes, and materials handling equipment. This cable is suitable for slow reeling and trailing applications.

Approvals:

AS/NZS 2802

Behaviour in flame and fire: Fire retardant

Temperature range:

Maximum operating temperature: +90°C

Minimum operating temperature: -25 °C

Flexibility: Flexible

Resistance to:

Chemical exposure: Very good/Frequent

Mechanical impact: Heavy

Water exposure: Immersion/Temporary coverage

Solar radiation and

weather exposure: Suitable for direct exposure

Cable design:

Composite screened power cores with two earth and one pilot core.

Core: Metal: tinned copper, three core plus two earths and one pilot.

Semiconductive barrier taped and elastomer screened.

Insulation: EPR (XR-EP-90) semiconductive elastomer screened.

Screen: Composite tinned annealed copper wire and polyester yarn screen, under a semiconductive tape.

Core colours: red, white, blue, braid tracers.

Earth: Two semiconductive elastomer covered tinned annealed copper wire earths disposed in the cable interstices.

Pilot: One, elastomer covered tinned annealed copper wire pilot disposed in the cable interstices.

Sheath: Extra heavy duty XHD-85-PCP, incorporating a polyaramid braid reinforcement.

Installation conditions:

In free air

Mobile equipment

What Is the AS/NZS Type 450 Mining Cable Designed For?

The AS/NZS Type 450 is a class 1 composite screened cable engineered for general-purpose use, particularly in reeling applications for heavy-duty mobile equipment. Its versatility makes it suitable for:

Drag-lines

Shovels

Excavators

Wharf cranes

Materials handling machinery

The cable accommodates voltage ratings from 3.3/3.3 kV to 33/33 kV, making it ideal for medium-voltage requirements. Its robust design also allows slow reeling and trailing, ensuring long-term reliability in challenging mining environments.

How Does Type 450 Compare with Other AS/NZS Mining Cables?

For engineers and procurement teams, choosing the right cable is crucial. The Type 450 stands out when compared to other common mining cables like Type 440 or Type 411.

Feature | Type 450 | Type 440 | Type 411 |

|---|---|---|---|

Voltage Range | 3.3–33 kV | 1.1–22 kV | 1.1–11 kV |

Flexibility | High | Medium | Very High |

Mechanical Impact Resistance | Heavy | Moderate | Moderate |

Reeling Capability | Slow reeling/trailing | Limited | High |

Thermal Rating | -25°C to +90°C | -25°C to +90°C | -25°C to +70°C |

Flame Retardant | Yes | Yes | Yes |

Typical Applications | Drag-lines, shovels, cranes | Hoists, conveyors | Superflex trailing cables |

Insight: Type 450 is particularly suitable for medium-voltage mobile applications, offering superior durability and reeling performance.

FAQ – What Are the Most Common Questions About Type 450 Cables?

1. Can Type 450 handle high mechanical impact?

Yes. Its reinforced XHD-85-PCP sheath and polyaramid braid make it ideal for heavy impact environments, including drag-lines and shovels.

2. Is the cable suitable for outdoor exposure?

Absolutely. The cable is UV-resistant, flame retardant, and water-resistant, allowing safe operation in harsh South African outdoor mining conditions.

3. What is the recommended voltage drop for installations?

Voltage drop varies by cable size and length. For instance, a 120 mm² conductor at 3.3 kV has a 3-phase voltage drop of 0.399 mV/A.m, which should be factored into power distribution calculations.

4. How does Type 450 compare with Type 440 for reeling?

Type 450 supports slow reeling and trailing for mobile equipment, while Type 440 is more suitable for stationary or short-length applications.

5. Can it be used in submerged conditions?

Type 450 can tolerate temporary immersion but should not be permanently submerged unless additional protective conduits are used.

6. How flexible is the cable for tight installations?

Type 450 is flexible enough for mobile equipment, but proper bending radii must be observed to maintain electrical and mechanical integrity.

What Are the Benefits of Choosing Feichun AS/NZS Type 450?

High durability: Resistant to mechanical, chemical, and environmental stresses

Wide voltage range: 3.3–33 kV for medium-voltage applications

Flexible: Suitable for slow reeling and mobile equipment

Compliant: Meets AS/NZS 2802 standards and flame retardant requirements

How to Choose the Right Conductor Size?

Selecting the correct conductor is vital to ensure minimal voltage drop and safe operation:

Nominal Area (mm²) | Recommended Applications |

|---|---|

25–50 | Small mobile machinery or short trailing runs |

70–120 | Medium-sized drag-lines, excavators, or cranes |

150–300 | Large shovels, wharf cranes, and long-distance power distribution |

Tip: Always consult with a qualified engineer to calculate load, voltage drop, and reel system requirements.

What Are the Key Takeaways for Mining Operations?

Durability and Reliability: Type 450 withstands mechanical, chemical, and environmental challenges

Voltage Versatility: 3.3–33 kV suits a wide range of medium-voltage applications

Flexibility: Supports reeling and trailing applications for mobile equipment

Safety Compliance: Flame retardant, fire-resistant, and electrically screened

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: