Anhui Feichun Kabel Khusus Co., Ltd

AS/NZS 2802 Type 441 Class 1 3.3–22kV Flexible Trailing & Reeling Cable with Central Pilot and Semiconductive Cradle

Feichun AS/NZS 2802 Type 441 Class 1 3.3–22kV Flexible Trailing & Reeling Cable with Central Pilot and Semiconductive Cradle

Applications :

Type 441 Class 1 series cable has lower insulation and sheath radials than Class 2 cables, designed for many uses, suitable for trailing and also suitable for reeling applications, have one central pilot and a semiconductive cradle supporting and protecting the power cores, which makes these cables less likely to be damaged from crushing and squashing.

Standards :

AS/NZS 2802:2000

AS/NZS 1125

AS/NZS 3808

AS/NZS 5000.1 |  |

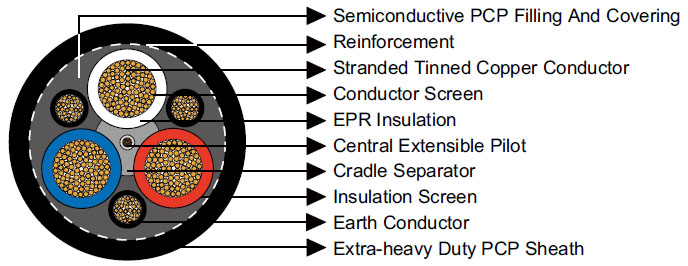

Construction :

3×Conductors | Flexible stranded tinned annealed copper conductor. |

Conductor Screen | Semiconductive compound (for cables having a voltage rating of 3.3/3.3kV and above). |

Insulation | EPR |

Insulation Screen | Semiconductive elastomer. |

Cradle Separator | Semiconductive PCP. |

Overall Core Screen | Semiconductive PCP filling and covering. |

3×Interstitial Earth Conductor | Semiconductive PCP covered flexible stranded tinned copper conductor. |

1×Central Extensible Pilot | EPR covered flexible stranded tinned copper conductor. |

Textile Reinforcement | Open-weave braid reinforcement. |

Sheath | Extra-heavy duty PCP sheath. Extra-heavy duty CPE/CSP sheath can be offered upon request. |

What Makes the Feichun AS/NZS 2802 Type 441 Class 1 Cable Ideal for Flexible Trailing and Reeling Applications?

The Feichun AS/NZS 2802 Type 441 Class 1 cable is rapidly gaining recognition in industrial and mining sectors, particularly in South Africa, for its versatile design, robust performance, and suitability for both trailing and reeling applications. But what exactly sets this cable apart, and why are engineers increasingly choosing it over other flexible power feeder cables?

What Is the AS/NZS 2802 Type 441 Class 1 Cable and How Does It Differ From Class 2?

The Type 441 Class 1 cable belongs to the AS/NZS 2802 standard, which governs flexible trailing and reeling cables for industrial applications. Compared to Class 2 cables, Class 1 variants have lower insulation and sheath radials, making them lighter and more flexible while maintaining mechanical and electrical integrity. This balance allows them to perform efficiently in dynamic applications, including:

Mining machinery feeders

Mobile industrial equipment

Reeling applications on winches and cable drums

Why Are Type 441 Cables Suitable for Trailing and Reeling Applications?

Trailing and reeling applications demand cables that resist mechanical stress, bending fatigue, and crushing. The Type 441 Class 1 cable addresses these challenges through:

Central semiconductive cradle: Provides structural support to prevent core deformation.

Flexible tinned copper conductors: Reduce risk of conductor breakage under repeated flexing.

Textile reinforcement: Adds abrasion resistance without compromising flexibility.

Optional CPE/CSP sheath: Increases toughness for harsh outdoor or mining environments.

These features make Type 441 ideal for mobile mining machines, conveyor systems, and industrial cranes, where conventional static cables would fail prematurely.

How Do You Compare Type 441 With Other Flexible Feeder Cables?

Engineers often compare Type 441 with other popular cables, such as Type 440 or Type 442, for similar industrial tasks.

Feature | Type 440 | Type 441 Class 1 | Type 442 |

|---|---|---|---|

Voltage Rating | 1.1–22kV | 3.3–22kV | 3.3–22kV |

Mechanical Protection | Moderate | High | Very High |

Suitable for Reeling | Limited | Excellent | Excellent |

Sheath Material Options | PVC/PCP | PCP/CPE/CSP | CPE/CSP |

Typical Applications | Static feeders | Trailing & Reeling | Heavy-duty reeling |

This comparison shows why Type 441 Class 1 is preferred when both flexibility and mechanical durability are required, especially in reeling operations.

Frequently Asked Questions (FAQ)

What voltage ranges does Type 441 Class 1 support?

Type 441 Class 1 cables are rated for 3.3–22kV, suitable for medium- to high-voltage industrial applications.

Can Type 441 cables be used in outdoor mining environments?

Yes, with optional CPE/CSP sheathing, these cables can withstand harsh weather, chemical exposure, and mechanical stress.

How does the central pilot conductor improve safety?

The central pilot allows real-time monitoring of cable integrity and can detect insulation breakdown or mechanical stress before faults occur.

How often should these cables be inspected in reeling applications?

Industry best practice is to inspect cables monthly for signs of crushing, abrasion, or insulation damage, and more frequently under heavy use.

What are the main advantages over Type 440 cables?

Type 441 Class 1 offers higher mechanical resistance, better reeling flexibility, and optional enhanced sheathing, making it more durable in dynamic operations.

Installation Recommendations and Best Practices

Routing: Avoid high-friction surfaces; use rollers or guide troughs.

Tension Control: Maintain consistent drum tension to prevent conductor stress.

Environmental Protection: Use sheaths appropriate for chemical or UV exposure.

Periodic Testing: Use pilot conductor to perform insulation resistance tests.

Implementing these strategies ensures reliable operation over years in industrial and mining applications.

Why Choose Feichun Type 441 for Your Next Project?

If you are managing mobile industrial equipment or mining operations, selecting the right flexible feeder cable is critical. The Feichun AS/NZS 2802 Type 441 Class 1 cable offers:

Flexible design suitable for reeling and trailing

Advanced protection with central pilot and semiconductive cradle

Compliance with AS/NZS 2802, 1125, 3808, and 5000.1 standards

Contact Feichun today to explore custom cable solutions or request a technical datasheet tailored to your operational needs.

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: