Anhui Feichun Special Cable Co.,Ltd Li.wang@feichuncables.com

AS/NZS 2802 Type 440 1.1-22 kV OPEN-CUT MINE CABLE

Feichun AS/NZS 2802 Type 440 1.1-22 kV OPEN-CUT MINE CABLE

Cable description:

Class 2 composite screened cable for general use.

Application: Trailing cable with good flexibility, and high resistance to abrasion and weathering. Suitable for long lengths of cable runs, in cases where the use of Type 409 or 441 could result in pilot resistances not meeting requirements. Cable suitable for trailing and most reeling applications.

Approvals: AS/NZS 2802

Behaviour in flame and fire: Fire retardant

Temperature range: Maximum operating temperature: +90°C

Minimum operating temperature: -25 °C

Flexibility: Flexible

Resistance to:

Chemical exposure: Very good/Frequent

Mechanical impact: Heavy

Water exposure: Immersion/Temporary coverage

Solar radiation and

weather exposure: Suitable for direct exposure

Cable design:

Composite screened power cores with three pilot cores.

Core: Metal: tinned copper, three core plus three pilots.

Conductor tape: 1.1/1.1 kV – polyester. 3.3 kV and above – semiconductive screen.

Insulation: EPR (R-EP-90) white

Insulation tape: 1.1/1.1 kV – proofed textile 3.3 kV and above – semiconductive screen

Screen: Composite screen (earth) of tinned annealed copper wire and polyester yarn.

Core colours: red, white, blue, braid tracers

Pilot: Three elastomer covered and proofed tape pilots disposed in the cable interstices.

Sheath: Heavy duty HD-85-PCP, incorporating a polyaramid yarn Kevlar® braid reinforcement (optional).

Installation conditions:

In free air

Mobile equipment

What Makes AS/NZS 2802 Type 440 Different from Other Mining Cables?

AS/NZS Type 440 is classified as a Class 2 composite screened mining cable, designed for general mining use where long cable lengths, pilot circuit stability, and mechanical robustness are critical.

Unlike Type 409 or Type 441, Type 440 is often selected when:

Long trailing distances risk pilot resistance drift

High mechanical impact and abrasion are expected

Frequent reeling or trailing movement is unavoidable

Key Design Philosophy

Composite earth screening for improved fault protection

Multiple pilot cores for monitoring and interlocking

Heavy-duty sheath for harsh, mobile mining environments

How Do Type 440 Variants Compare (1.1 kV vs 3.3 kV vs 6.6–22 kV)?

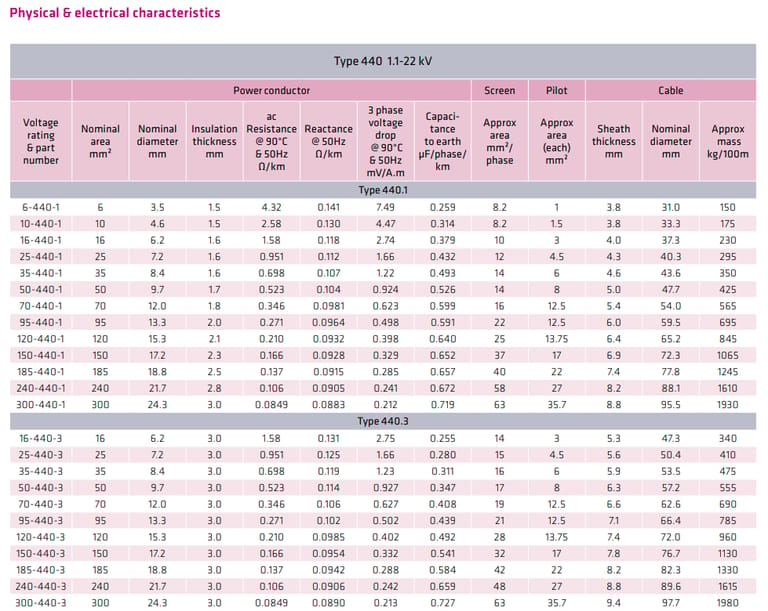

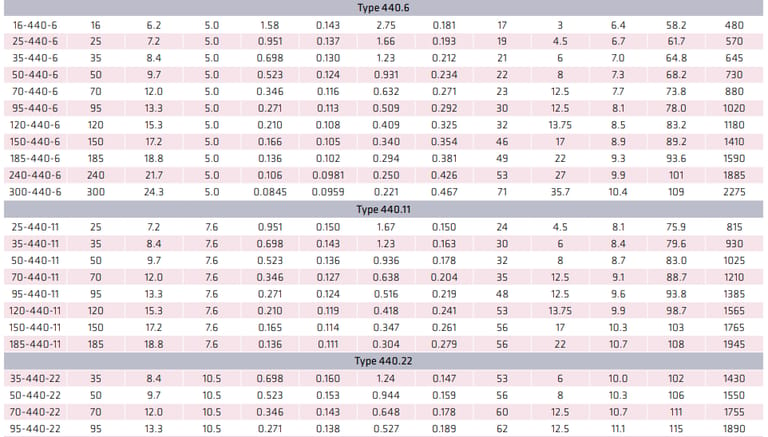

Type 440 Variant Comparison Table

Type | Typical Voltage | Insulation Thickness | Typical Application |

|---|---|---|---|

Type 440.1 | 1.1 kV | ~1.5–3.0 mm | Low-voltage mobile equipment |

Type 440.3 | 3.3 kV | ~3.0 mm | Medium-duty open-cut mining |

Type 440.6 | 6.6 kV | ~5.0 mm | High-power shovels & conveyors |

Type 440.11 | 11 kV | ~7.6 mm | Long-distance trailing |

Type 440.22 | 22 kV | ~10.5 mm | High-capacity mining systems |

Where Is AS/NZS Type 440 Mining Cable Commonly Used?

What Mining Equipment Uses Type 440 Cables?

Type 440 is widely used for:

Electric rope shovels

Draglines

Mobile crushers

High-power conveyors

Bucket wheel reclaimers

It is suitable for:

Trailing applications

Most reeling systems

Free-air installation

What Installation Conditions Should Be Considered for Type 440?

Best-Practice Installation Advice

Avoid tight bending radii during deployment

Use cable rollers on long runs

Ensure proper earthing continuity checks

Select Kevlar-reinforced sheath for frequent reeling

Match pilot resistance requirements to protection systems

Correct installation significantly extends service life and improves safety compliance.

How Does Type 440 Compare with Type 409 and Type 441?

Feature | Type 409 | Type 440 | Type 441 |

|---|---|---|---|

Pilot Stability (long runs) | Moderate | Excellent | Good |

Mechanical Strength | Good | Very High | High |

Reeling Suitability | Limited | Yes | Yes |

Voltage Range | Limited | 1.1–22 kV | Medium |

Type 440 is often chosen when Type 409 or Type 441 cannot meet pilot resistance or mechanical durability requirements.

Frequently Asked Questions About AS/NZS Type 440 Mining Cable

Is Type 440 suitable for both trailing and reeling applications?

Yes. It is specifically designed for trailing and most reeling applications, especially where mechanical stress is high.

Can Type 440 be used in harsh weather conditions?

Absolutely. It is resistant to UV, rain, temporary water immersion, and extreme temperature variations.

Why choose EPR insulation instead of XLPE?

EPR offers superior flexibility, better thermal ageing, and improved resistance to cracking in mobile mining environments.

Does Type 440 comply with flame retardancy requirements?

Yes. The cable is fire retardant and compliant with AS/NZS 2802 flame behaviour requirements.

Who Should Choose Feichun AS/NZS 2802 Type 440 Mining Cable?

Feichun Type 440 is ideal for:

Open-cut and surface mines

High-power mobile equipment

Long trailing cable routes

Operations prioritising safety, durability, and lifecycle cost

If you are evaluating AS/NZS Type 440 mining cables for long trailing or high-power applications, Feichun offers customised conductor sizes, voltage classes, and reinforcement options to match your mine’s exact operating conditions.

Contact our technical team for:

Cable selection guidance

Datasheets and drawings

Project-specific recommendations

Email: Li.wang@feichuncables.com

Feichun Mining Cable

Durable mining cables for tough environments and operations

Contact us:

© 2025. All rights reserved.