Anhui Feichun Kabel Khusus Co., Ltd

AS/NZS 2802 Type 412 1.1/1.1KV Pliable Armoured Feeder Cable for Sand Mining Applications

Feichun AS/NZS 2802 Type 412 1.1/1.1KV Pliable Armoured Feeder Cable for Sand Mining Applications

Applications :

These cables with green/yellow earths and pliable armour for mechanical protection may be used in applications where damage is likely and armour can reduce cases of costly downtime, suitable installed as feeder cables in sand mining operations.

Standards :

AS/NZS 2802:2003

AS/NZS 1125

AS/NZS 3808

AS/NZS 5000.1 |  |

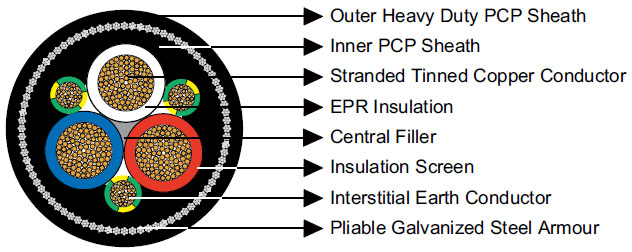

Construction :

3×Conductors | Flexible stranded tinned annealed copper conductor. |

Insulation | EPR. |

Insulation Screen | Semiconductive elastomer. |

Filler | Elastomer centre filler. |

3×Interstitial Earth Conductor | EPR covered flexible stranded tinned copper conductor. |

Inner Sheath | PCP sheath. CPE/CSP sheath can be offered upon request. |

Pliable Armour | Galvanized low carbon (mild) steel strands. |

Outer Sheath | Heavy duty PCP sheath. Heavy duty CPE/CSP sheath can be offered upon request. |

Dimensions and Weight :

Nominal | Strand | Insulation | Earth Conductor | Pliable | Thickness of | Nominal | Nominal | ||

Strand Size | Thickness | Inner | Outer | ||||||

mm² | No/mm | mm | No/mm | mm² | No/mm | mm | mm | mm | kg/100m |

Type 412.1 Class2 | |||||||||

16 | 126/0.40 | 1.6 | 81/0.30 | 0.6 | 7/0.90 | 2.5 | 3.8 | 38.3 | 265 |

25 | 209/0.40 | 1.6 | 81/0.30 | 0.6 | 7/0.90 | 2.5 | 3.8 | 38.4 | 294 |

35 | 285/0.40 | 1.6 | 81/0.30 | 0.6 | 7/0.90 | 2.5 | 4.0 | 44.6 | 402 |

50 | 380/0.40 | 1.7 | 120/0.30 | 0.8 | 7/0.90 | 2.5 | 4.4 | 49.2 | 500 |

70 | 203/0.67 | 1.8 | 39/0.67 | 0.8 | 7/0.90 | 2.5 | 4.8 | 55.4 | 655 |

95 | 259/0.67 | 2.0 | 48/0.67 | 0.8 | 7/0.90 | 2.5 | 5.4 | 60.1 | 775 |

120 | 336/0.67 | 2.1 | 60/0.67 | 1.0 | 7/0.90 | 3.5 | 5.8 | 68.1 | 990 |

150 | 427/0.67 | 2.3 | 77/0.67 | 1.0 | 7/0.90 | 3.5 | 6.3 | 73.8 | 1186 |

185 | 518/0.67 | 2.5 | 91/0.67 | 1.0 | 7/0.90 | 3.5 | 6.8 | 80.2 | 1360 |

240 | 672/0.67 | 2.8 | 119/0.67 | 1.2 | 7/0.90 | 3.5 | 7.5 | 88.7 | 1670 |

300 | 854/0.67 | 3.0 | 156/0.67 | 1.2 | 7/1.25 | 4.5 | 8.2 | 100.9 | 2200 |

When sand mining operations demand continuous power delivery under high mechanical stress, selecting the right mining feeder cable becomes critical. Among the most reliable solutions is the Feichun AS/NZS 2802 Type 412 1.1/1.1kV Pliable Armoured Feeder Cable, specifically engineered for environments where abrasion, impact, and downtime risks are high.

What Is AS/NZS 2802 Type 412 and How Does It Differ from Other Mining Cables?

AS/NZS 2802 Type 412 is a low-voltage (1.1/1.1kV) pliable armoured mining feeder cable designed for mobile and semi-fixed power distribution in mining environments.

Unlike rigid armoured cables, Type 412 combines mechanical protection with flexibility, making it ideal for sand mining where cables are frequently exposed to:

Moving machinery

Shifting ground and slurry

Mechanical impact from loaders and conveyors

Frequent repositioning

Its defining feature is pliable galvanised steel wire armour, which reduces cable damage while maintaining flexibility.

How Is the Feichun AS/NZS 2802 Type 412 Cable Constructed?

The cable’s layered construction balances electrical performance, flexibility, and mechanical protection.

What Type of Conductors Are Used in Type 412 Mining Cable?

3 × Flexible stranded tinned annealed copper conductors

Excellent conductivity and corrosion resistance

High strand count improves flexibility under repeated movement

Why Is EPR Insulation Used in Type 412 Cables?

EPR (Ethylene Propylene Rubber) insulation offers:

High dielectric strength

Resistance to moisture and chemicals

Stability under heat and mechanical stress

What Is the Role of the Insulation Screen?

Semiconductive elastomer screen

Ensures uniform electric field distribution

Reduces partial discharge risk

How Is Earthing Achieved in Type 412 Mining Cables?

3 × interstitial earth conductors

Flexible stranded tinned copper, EPR covered

Green/yellow identification for safety compliance

Provides reliable fault current paths

Why Is Pliable Armour Important in Sand Mining?

Galvanised low-carbon steel wire armour

Protects against crushing, abrasion, and impact

Maintains flexibility unlike rigid steel tape armour

Reduces downtime caused by accidental cable damage

What Sheathing Materials Are Used?

Inner sheath: PCP (Polychloroprene)

Outer sheath: Heavy-duty PCP

Optional upgrades: CPE or CSP for enhanced oil and chemical resistance

Where Is AS/NZS 2802 Type 412 Commonly Used in Sand Mining?

Why Is Type 412 Ideal for Sand Mining Feeder Applications?

Sand mining environments expose cables to:

Abrasive sand particles

Wet and muddy conditions

Heavy mobile equipment

Frequent mechanical contact

Type 412’s pliable armour and robust PCP sheath reduce sheath cuts and conductor damage, lowering maintenance costs.

Typical Applications Include:

Power feeders for sand dredges

Supply cables for wash plants

Conveyor and screening equipment

Mobile crushers and loaders

Temporary power distribution in open-pit sand operations

How Does Type 412 Compare with Other AS/NZS Mining Cables?

Type 412 vs Type 210 Mining Cable

Feature | Type 412 | Type 210 |

|---|---|---|

Armour | Pliable steel wire | Unarmoured |

Mechanical protection | Very high | Moderate |

Flexibility | High | Very high |

Typical use | Feeder cables | Trailing cables |

Downtime risk | Lower | Higher |

Conclusion: Type 412 is preferred where mechanical damage risk is high, while Type 210 suits lighter trailing duties.

What Installation Practices Improve Type 412 Cable Performance?

How Should Type 412 Be Installed in Sand Mining Sites?

Avoid excessive tension during pulling

Maintain recommended minimum bending radius

Provide proper cable support at entry points

Use protective ramps at vehicle crossing zones

Can Type 412 Be Buried Directly in Sand?

Yes, but it is recommended to:

Use sand bedding free of sharp stones

Avoid direct burial in high-traffic areas without protection

Inspect regularly for sheath wear

Frequently Asked Questions (FAQ)

Is AS/NZS 2802 Type 412 suitable for continuous flexing?

It is designed for limited movement and repositioning, not constant reeling like trailing cables.

Can CPE or CSP sheaths be specified instead of PCP?

Yes. CPE/CSP options are recommended for oil-rich or chemically aggressive environments.

Does Type 412 meet mining safety earthing requirements?

Yes. The three interstitial earth conductors ensure effective grounding and fault protection.

Is Type 412 acceptable for export projects outside Australia?

Yes. It is widely accepted in South Africa, Southeast Asia, and African mining projects due to its robust design.

Why Choose Feichun AS/NZS 2802 Type 412 for Your Mining Project?

Feichun Type 412 offers:

Proven performance in abrasive sand mining

Reduced downtime through pliable armour

Compliance with international standards

Flexible customisation options

Competitive lifecycle cost

Planning a sand mining or mineral processing project?

Contact Feichun Cable today to request technical datasheets, sizing assistance, or project-specific quotations for AS/NZS 2802 Type 412 mining feeder cables engineered for durability and safety.

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: