Anhui Feichun Special Cable Co.,Ltd Li.wang@feichuncables.com

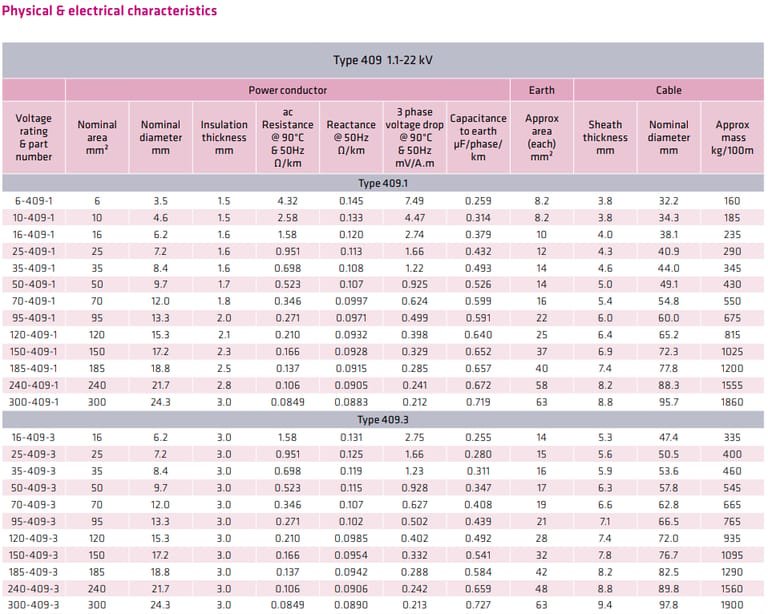

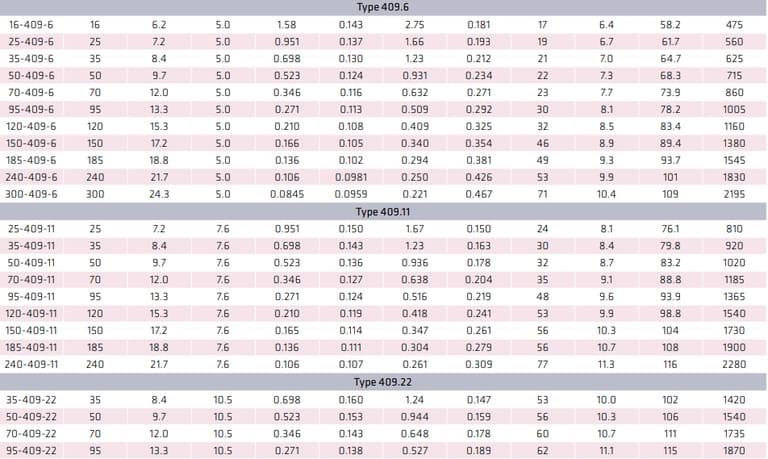

AS/NZS 2802 Type 409 1.1-22 kV OPEN-CUT MINE CABLE

Feichun AS/NZS 2802 Type 409 1.1-22 kV OPEN-CUT MINE CABLE

Cable description:

Class 2 composite screened cable with central pilot.

Application:

Heavy duty trailing cable with good flexibility and high resistance to abrasion and weathering. Suitable for pumps, shovels, draglines, blasthole drill, etc. For improved performance, all cables (except 409.1 below 50 mm) incorporate a polyaramid yarn Kevlar® braid sheath reinforcement for exceptional tear and cut-through resistance. Cable designed for trailing and most reeling applications.

Approvals:

AS/NZS 2802

Behaviour in flame and fire:

Fire retardant

Temperature range:

Maximum operating temperature: +90°C

Minimum operating temperature: -25 °C

Flexibility: Flexible

Resistance to:

Chemical exposure: Very good/Frequent

Mechanical impact: Heavy

Water exposure: Immersion/Temporary coverage

Solar radiation and

weather exposure: Very good/Frequent

Cable design:

Composite screened power cores with a single extensible pilot.

Core: Metal: tinned copper, three core plus central pilot.

Conductor tape: 1.1/1.1 kV – polyester. 3.3 kV and above – semiconductive screen.

Insulation: Class 2 EPR (R-EP-90).

Insulation tape: 1.1/1.1 kV – proofed textile 3.3 kV and above – semiconductive screen

Screen: Composite screen (earth) of tinned annealed copper wire and polyester yarn.

Core colours: red, white, blue.

Pilot: Single, in centre of cable.

Maximum DC resistance;

3 Ω/100 m for power cores to 35 mm².

2 Ω/100 m for power conductors above 35 mm².

Sheath: Heavy duty HD-85-PCP, incorporating a polyaramid yarn Kevlar® braid reinforcement (optional).

Installation conditions:

In free air

Mobile equipment

Class 2 cables use standard insulation and sheath materials. For higher performance applications, particularly reeling operations.

What Is AS/NZS 2802 Type 409 Mining Cable Designed For?

AS/NZS 2802 Type 409 is a Class 2 composite screened open-cut mine cable with a central extensible pilot, specifically designed for:

Heavy-duty trailing applications

Most reeling operations

Harsh abrasive and weather-exposed environments

It is commonly used to power:

Electric shovels

Draglines

Pumps

Blasthole drills

Large mobile mining equipment

The design focuses on mechanical durability, electrical stability, and operational safety under continuous movement.

How Does Type 409 Perform in Fire and Extreme Environments?

Is Type 409 Flame Retardant?

Yes. Type 409 is fire-retardant and compliant with AS/NZS 2802 flame behavior requirements, reducing flame propagation risk on mine benches and pits.

What Environmental Conditions Can It Withstand?

Operating temperature: –25 °C to +90 °C

Water exposure: Immersion / temporary flooding

Chemical resistance: Very good (frequent exposure)

UV & weather: Excellent resistance

This makes it suitable for South African, Australian, and African open-cut climates.

How Does Type 409 Compare with Other Mining Cables?

Type 409 vs Type 440 (AS/NZS 2802)

Feature | Type 409 | Type 440 |

|---|---|---|

Application | Trailing & reeling | Fixed & semi-fixed |

Flexibility | High | Moderate |

Reinforcement | Kevlar® optional | Limited |

Best use | Mobile equipment | Feeders |

Conclusion: Type 409 is superior for moving equipment.

Type 409 vs Type 441

Type 441 focuses on stationary MV distribution

Type 409 is optimized for continuous movement

What Are the Recommended Installation Practices for Type 409?

How Should Type 409 Be Installed?

Install in free air

Avoid sharp edges and excessive crushing

Use proper bend radius, especially for 11–22 kV variants

Is Type 409 Suitable for Reeling?

Yes.

For frequent reeling:

Select Kevlar® reinforced sheath

Ensure drum diameter matches cable size

Avoid over-tensioning

Frequently Asked Questions About AS/NZS Type 409 Mining Cable

Is Type 409 suitable for underground mining?

Primarily designed for open-cut mines, but can be used in large underground caverns with adequate ventilation.

Why is a central pilot required?

The pilot enables:

Earth continuity monitoring

Control circuits for mobile equipment safety

Does Type 409 meet AS/NZS 2802 compliance?

Yes, it is fully compliant with AS/NZS 2802 open-cut mine cable requirements.

How long is the expected service life?

With correct installation, 5–10+ years depending on duty cycle.

Why Choose Feichun AS/NZS 2802 Type 409 Mining Cable?

Full AS/NZS 2802 compliance

Wide voltage range (1.1–22 kV)

Proven performance in South African mines

Optional Kevlar® reinforcement for extreme duty

Optimised electrical and mechanical balance

How Do You Select the Right Type 409 Cable?

Selecting the correct Type 409 variant depends on:

Voltage level

Equipment type

Trailing or reeling frequency

Environmental severity

👉 Contact Feichun’s mining cable specialists to receive:

Cable selection support

Technical datasheets

Application-specific recommendations for your mine

Feichun Mining Cable

Durable mining cables for tough environments and operations

Contact us:

© 2025. All rights reserved.