Anhui Feichun Special Cable Co.,Ltd Li.wang@feichuncables.com

AS/NZS 1972 Type A and Type B 1.1 kV MINE FEEDER CABLE

Feichun AS/NZS 1972 Type A and Type B 1.1 kV MINE FEEDER CABLE

Cable description:

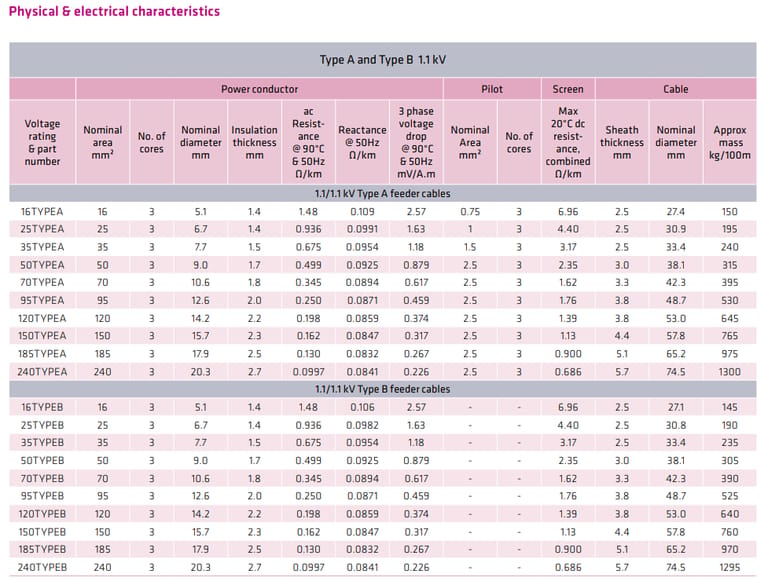

1.1/1.1 kV feeder cables to AS/NZS 1972.

Application:

Individually screened power cores. 1.1/1.1 kV cable suitable for applications where the conductivity of the combined screens must meet the requirements of AS/NZS 1972. Type A cables have three pilot cores. Type B cables have no pilots. For use between transportable substations and associated equipment, where the cable has to be frequently moved.

Approvals: AS/NZS 1972

Behaviour in flame and fire: Fire retardant

Temperature range: Maximum operating temperature: +90°C

Minimum operating temperature: -25 °C

Flexibility: Semi-flexible

Resistance to:

Chemical exposure: Very good/Frequent

Mechanical impact: Heavy

Water exposure: Immersion/Temporary coverage

Solar radiation and

weather exposure: Excellent/Permanent.

Cable design:

EPR insulated, screened, PCP sheathed cable.

Core: Metal: Tinned Copper, three core (plus three symmetrical pilots in Type A).

Conductor tape: Polyester

Insulation: EPR (R-EP-90) Core colours: red, white, blue, under a semiconductive tape.

Earth: Screen (earth) of tinned annealed copper wire.

Pilot: Three elastomer covered in the cable interstices (Type A only).

Sheath: Heavy duty HD-85-PCP.

Installation conditions:

In free air

In duct

Mobile equipment

What Is an AS/NZS 1972 Type A or Type B 1.1 kV Mine Feeder Cable?

AS/NZS 1972 is a dedicated standard for flexible and semi-flexible feeder cables used in mining and heavy industrial environments.

Feichun Type A and Type B 1.1/1.1 kV feeder cables are designed to supply power between transportable substations and associated mining equipment, especially where cables are frequently moved.

Both cable types share the same voltage rating, insulation system, mechanical robustness, and fire-retardant behaviour.

The key distinction lies in pilot cores.

What Is the Main Structural Difference Between Type A and Type B Cables?

Type A vs Type B: Core Configuration Explained

Feature | Type A | Type B |

|---|---|---|

Power cores | 3 | 3 |

Pilot cores | 3 symmetrical pilots | None |

Individual core screening | Yes | Yes |

Combined screen conductivity | Meets AS/NZS 1972 | Meets AS/NZS 1972 |

Typical use | Interlocked or controlled systems | Direct power supply |

Type A cables include three elastomer-insulated pilot cores, located in the interstices between power cores.

Type B cables omit pilot cores, resulting in a slightly simpler and marginally lighter construction.

Where Are AS/NZS 1972 Type A and Type B Cables Typically Used?

What Are the Typical Applications in Mining?

Between transportable substations and load centres

Mobile mining equipment power feeds

Temporary or semi-permanent power circuits

Areas requiring frequent cable relocation

Type A Is Commonly Used When:

Pilot circuits are required for:

Earth-fault monitoring

Interlocking systems

Remote shutdown or signalling

Compliance specifications explicitly require pilot cores

Type B Is Commonly Used When:

Power distribution is straightforward

No control or monitoring via pilot cores is required

Cost and simplicity are priorities

How Are These Cables Installed?

What Installation Conditions Are They Designed For?

Feichun AS/NZS 1972 feeder cables are suitable for:

Free-air installation

Duct installation

Mobile equipment connections

What Installation Best Practices Should Be Followed?

Maintain minimum bending radius during installation

Avoid sharp edges or unprotected steel supports

Use proper cleats for vertical or inclined runs

Inspect sheath regularly in high-traffic areas

How Do These Cables Perform in Harsh Mining Environments?

Environmental and Mechanical Resistance

Property | Performance |

|---|---|

Flame behaviour | Fire-retardant |

Mechanical impact | Heavy duty |

Chemical exposure | Very good (frequent exposure) |

Water exposure | Immersion / temporary coverage |

UV & weather resistance | Excellent (permanent exposure) |

This makes them suitable for open-cast mines, underground haulages, and surface substations in Southern Africa.

Are These Cables Used in South African Mines?

Platinum Mine Feeder Upgrade

In a North West Province platinum mine, Feichun AS/NZS 1972 Type A 1.1 kV feeder cables were selected to connect transportable substations supplying underground conveyors.

Why Type A was chosen:

Pilot cores integrated into earth-fault monitoring systems

Excellent performance under repeated relocation

Strong resistance to oil and moisture in humid stopes

In contrast, Type B cables were used on surface feeder runs where no pilot circuits were required, optimising cost without compromising safety.

FAQ

What Is the Real Difference Between Type A and Type B Feeder Cables?

The only functional difference is the presence of pilot cores in Type A. Electrically and mechanically, both perform the same.

Can Type B Be Used Instead of Type A to Save Cost?

Only if pilot circuits are not required. Substituting Type B where pilots are specified can lead to non-compliance and operational risk.

Are These Cables Suitable for Continuous Movement?

Yes. They are classified as semi-flexible and specifically designed for frequently moved feeder applications.

Are Feichun AS/NZS 1972 Cables Flame Retardant?

Yes. They are fire-retardant and suitable for underground mining environments.

How Do You Choose the Right Size and Type?

Ask the following questions:

Do I need pilot cores for control or monitoring?

What is the load current and voltage drop limit?

Will the cable be frequently moved?

Is chemical or water exposure expected?

Answering these determines Type A vs Type B and conductor size.

Why Choose Feichun AS/NZS 1972 Mine Feeder Cables?

Proven compliance with AS/NZS 1972

Robust EPR + PCP construction

Designed for real mining abuse

Successfully deployed in South African mining operations

Need Help Selecting the Right Mine Feeder Cable?

If you are planning a mine power upgrade, substation relocation, or equipment expansion, selecting the correct feeder cable is critical for safety, compliance, and long-term reliability.

Contact Feichun technical specialists to:

Compare Type A vs Type B for your application

Calculate voltage drop and conductor size

Ensure compliance with AS/NZS and mining specifications

Feichun Mining Cable

Durable mining cables for tough environments and operations

Contact us:

© 2025. All rights reserved.