Anhui Feichun Kabel Khusus Co., Ltd

AS/NZS 1972 Type 2S, Type 2S.3 MINE FEEDER CABLE

Cable description:

Elastomer insulated and sheathed, screened cable.

Application:

Cables designed for wiring mobile equipment such as continuous miners, shuttle cars, road headers, and personnel transporters. 0.6/1 kV Type 2S cables are sheathed and do not require further mechanical protection when used in external (non-protected) installations. They are used for the interconnection of equipment, for example control boxes, motors, etc., and may be used for longwall lighting systems.

Approvals: AS/NZS 1972

Behaviour in flame and fire: Fire retardant

Temperature range: Maximum operating temperature: +90°C

Minimum operating temperature: -25 °C

Flexibility: Flexible

Resistance to:

Chemical exposure: Very good/Frequent

Mechanical impact: Heavy

Water exposure: Immersion/Temporary coverage

Solar radiation and

weather exposure: Very good/Frequent

Cable design:

EPR insulated, screened, CPE sheathed cable.

Core: Metal: Tinned annealed copper.

Insulation: EPR (R-EP-90).

Pilot (where required): Tinned annealed copper, R-EP-90 insulated (screened when individual power cores are screened). Screen: Tinned copper wire and polyester yarn composite braid screened. Cables can be individually (as displayed) or collectively screened.

Sheath: HD-90-CPE Black.

Installation conditions:

In free air

Mobile equipment

Machines

What Is the AS/NZS 1972 Type 2S Mine Feeder Cable Designed For?

AS/NZS 1972 Type 2S cables are elastomer-insulated and sheathed, screened mining cables specifically engineered for mobile and semi-mobile mining equipment.

They are commonly used to supply power to:

Continuous miners

Shuttle cars

Roadheaders

Personnel transporters

Longwall lighting systems

Control boxes and underground motors

A key advantage is that 0.6/1 kV Type 2S cables do not require additional mechanical protection when installed externally, making them ideal for non-protected mining environments.

What Makes Type 2S.3 Different from Standard Type 2S Cables?

The Type 2S.3 cable is essentially a higher-voltage evolution of the Type 2S design.

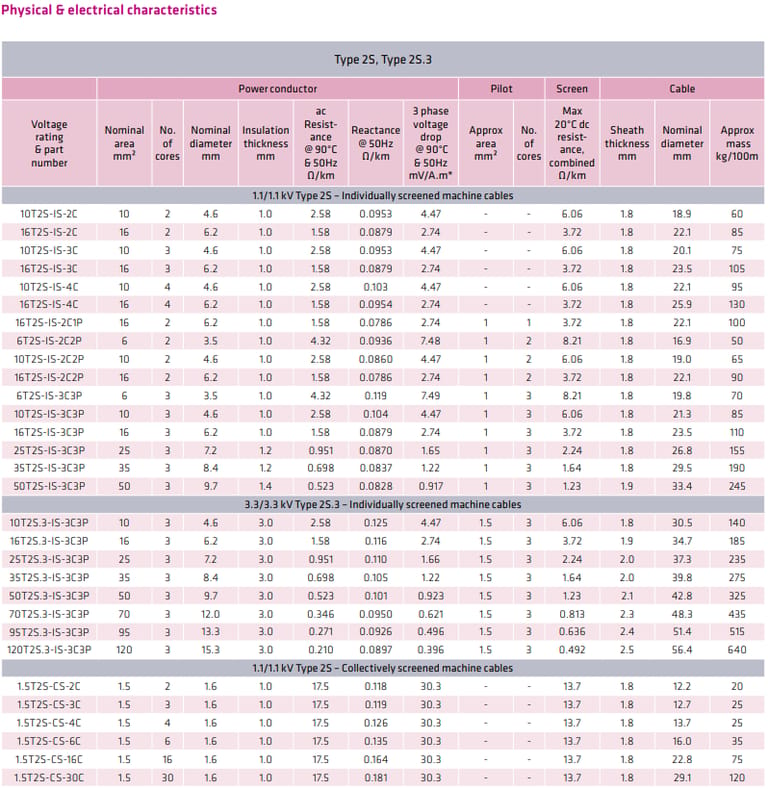

Feature | Type 2S | Type 2S.3 |

|---|---|---|

Voltage rating | 1.1/1.1 kV | 3.3/3.3 kV |

Typical application | Low-voltage mobile equipment | Medium-voltage mobile machines |

Insulation thickness | ~1.0–1.4 mm | 3.0 mm |

Power transmission | Short to medium distances | Higher power, longer distances |

Mechanical robustness | Heavy-duty | Heavy-duty (enhanced insulation) |

If your operation involves higher power demand or longer feeder lengths, Type 2S.3 is the safer and more efficient choice.

Where Are Type 2S and Type 2S.3 Cables Typically Installed?

What Installation Conditions Are These Cables Designed For?

These cables are suitable for:

Installation in free air

Mobile equipment trailing applications

Heavy mining machinery with constant movement

They are not rigid power cables—they are engineered to flex, twist, and endure vibration.

Which Type 2S Cable Should You Choose for Your Application?

How Do Individually Screened and Collectively Screened Cables Compare?

Feature | Individually Screened (IS) | Collectively Screened (CS) |

|---|---|---|

Fault localisation | Excellent | Moderate |

EMI control | Superior | Good |

Typical use | Power + pilot cores | Multi-core control cables |

Cost | Higher | More economical |

What Installation Best Practices Should Be Followed?

Avoid tight bending radii during installation

Use cable handling equipment for large cross-sections

Inspect sheath integrity regularly in mobile zones

Ensure proper earthing of screening layers

Correct installation significantly extends service life and safety compliance.

Frequently Asked Questions (FAQ)

Can Type 2S cables be used without additional mechanical protection?

Yes. 1.1 kV Type 2S cables are designed for external, non-protected installations, provided installation guidelines are followed.

Are Type 2S.3 cables suitable for continuous flexing?

Yes. Despite their higher voltage rating, Type 2S.3 cables maintain excellent flexibility, making them suitable for mobile mining equipment.

Do these cables meet flame retardant requirements?

Yes. Both Type 2S and Type 2S.3 cables are fire retardant and comply with AS/NZS 1972 flame performance requirements.

Can pilot cores be integrated into Type 2S cables?

Yes. Many designs include tinned copper pilot cores, insulated with R-EP-90 and screened where required.

Why Choose Feichun AS/NZS 1972 Type 2S and Type 2S.3 Mine Feeder Cables?

Feichun mine feeder cables offer:

Full compliance with AS/NZS 1972

Proven performance in Australian and South African mining environments

Optimised balance of flexibility, durability, and electrical efficiency

Wide size range for precise engineering selection

How Can You Select the Right Mine Feeder Cable for Your Project?

If you are planning or upgrading a mining power system and need:

Cable selection guidance

Voltage drop calculations

Application-specific recommendations

Compliance support for AS/NZS or African mining projects

👉 Contact Feichun’s technical team to discuss your mine feeder cable requirements and ensure safe, efficient, and compliant power delivery. Email: Li.wang@feichuncables.com

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: