Anhui Feichun Kabel Khusus Co., Ltd

AS/NZS 1972 Type 1 1.1 kV Mining Feeder Cable

AS/NZS 1972 Type 1 1.1 kV Mining Feeder Cable

Cable description: PVC insulated and covered, screened cable.

Application:

Cable designed for the wiring of mobile equipment such as continuous miners, shuttle cars, road headers, personnel transports, etc. Type 1 cables require further mechanical protection when used in external (non-protected) installations. They are used for the interconnection of equipment, for example control boxes, motors, etc. Cables rated in excess of 20 amps are electrically symmetrical.

Approvals: AS/NZS 1972

Behaviour in flame and fire: No fire performance

Temperature range: Maximum operating temperature: +90°C

Minimum operating temperature: 0°C

Flexibility: Flexible

Resistance to:

Chemical exposure: Very good/Frequent

Mechanical impact: Light

Water exposure: Water splashes

Solar radiation and

weather exposure: Very good/Frequent

Cable design:

PVC insulated, screened, PVC sheathed cable.

Core: Metal: Tinned annealed copper

Insulation: Heat resistant V-90 PVC.

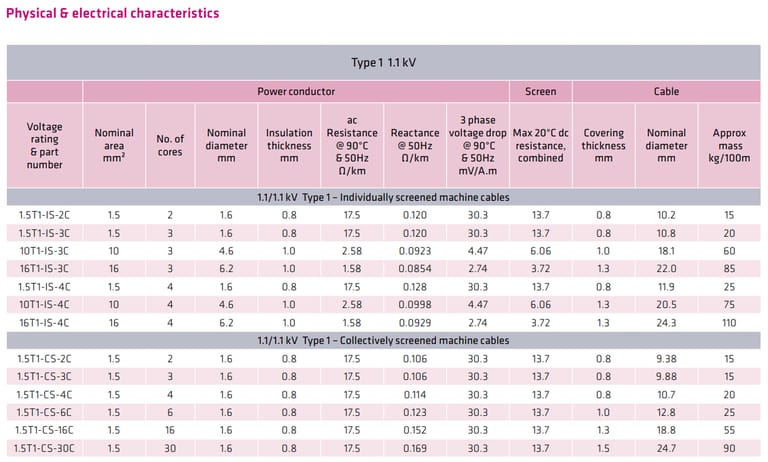

Screen: Tinned copper wire and polyester yarn composite braid screened. Cables can be individually or collectively screened. Cover: Heat resistant 5V-90 PVC.

Installation conditions:

In duct

Machines

What Is the AS/NZS 1972 Type 1 1.1 kV Mine Feeder Cable Designed For?

The AS/NZS 1972 Type 1 Mine Feeder Cable is a PVC insulated, PVC sheathed, screened flexible mining cable specifically designed for power and control interconnection of mobile mining equipment.

It is widely used in:

Underground coal and hard-rock mines

Semi-protected mining environments

Machine-to-machine power and control wiring

Feichun Type 1 cables are intended for ducted or machine installations and require additional mechanical protection when installed in exposed or harsh external conditions.

Why Is the Feichun Type 1 Cable Commonly Used on Mobile Mining Equipment?

Mining machinery such as continuous miners, shuttle cars, roadheaders, and personnel transport vehicles requires cables that are:

Flexible

Electrically stable

Resistant to oils, chemicals, and moisture splashes

The Type 1 design provides:

Reliable screening for electrical symmetry and interference control

Excellent chemical and environmental resistance

Lightweight construction compared with heavy-duty trailing cables

This makes it ideal for interconnection between motors, control boxes, and auxiliary systems.

Does the Cable Offer Fire Resistance?

No.

AS/NZS 1972 Type 1 cables have no dedicated fire performance rating, meaning:

They are not flame-retardant or fire-resistant

They should not be used in fire-critical escape routes

For fire-rated requirements, higher-category mining cables should be selected.

How Does Type 1 Compare with Other Mining Cable Types?

Type 1 vs Heavy-Duty Trailing Cables

Feature | Type 1 | Trailing Cable |

|---|---|---|

Flexibility | High | High |

Mechanical protection | Light | Very heavy |

Installation | Duct/machine | Dragged on floor |

Fire performance | None | Often flame-retardant |

Cost | Lower | Higher |

Type 1 vs Type 2 or Type 3 Mining Cables

Aspect | Type 1 | Higher Types |

|---|---|---|

Mechanical resistance | Light | Medium–Heavy |

Fire rating | None | Often required |

Installation environment | Semi-protected | Harsh/exposed |

What Are the Recommended Installation Conditions?

Where Should Type 1 Cables Be Installed?

✔ In ducts

✔ Inside machinery

✔ Within protective conduits

❌ Not recommended for:

Direct burial

Dragging on mine floors

Exposed mechanical abuse

What Installation Tips Improve Service Life?

Always use additional mechanical protection in exposed areas

Maintain proper bending radius

Ensure screen termination is correctly grounded

Avoid sharp edges and unsupported spans

Frequently Asked Questions (FAQ)

Is AS/NZS 1972 Type 1 suitable for external mining installations?

Only if additional mechanical protection is provided. It is not designed for unprotected external use.

Can Type 1 cables be used for control and power together?

Yes. Multi-core and screened designs make them ideal for combined power and control circuits.

Are Type 1 cables symmetrical?

Cables rated above 20 A are electrically symmetrical, improving balanced three-phase performance.

Does the cable resist chemicals and moisture?

Yes. It offers very good resistance to chemicals, water splashes, and weather exposure.

Is this cable compliant with mining standards?

Yes. It is fully compliant with AS/NZS 1972 requirements.

What Should Buyers Consider Before Selecting a Type 1 Mine Feeder Cable?

Ask the following:

Is the installation protected or exposed?

Is fire performance required?

Do I need individual or collective screening?

What current and voltage margins are needed?

Why Choose Feichun AS/NZS 1972 Type 1 Mine Feeder Cable?

Feichun’s Type 1 cables deliver:

Consistent electrical performance

Proven durability in mining environments

Broad configuration options

Compliance with recognised mining standards

They are a cost-effective and technically sound solution for machine interconnection and control wiring in mines.

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: