Anhui Feichun Kabel Khusus Co., Ltd

AS/NZS 1972 6.35/11 kV Copper Mining Feeder Cable

Cable description:

Three core copper wire screened armoured to AS/NZS 1972.

Application:

Suitable as primary supply for mines and industrial networks.

Approvals: AS/NZS 1972

Behaviour in flame and fire:

Flame retardant

Temperature range:

Maximum operating temperature: +90°C

Minimum operating temperature: -25 °C

Minimum bending radius Installed cables: 12D

Flexibility: Rigid

Resistance to:

Chemical exposure: Very good/Frequent

Mechanical impact: Very heavy

Water exposure: Water splashes

Solar radiation and

weather exposure: Very good/Frequent

Cable design:

XLPE insulated, screened, GSW armoured, PVC sheathed cable.

Core: Metal: Plain circular compacted copper.

Conductor screen: Extruded semiconducting compound, bonded to the insulation and applied in the same operation as the insulation.

Insulation: Cross Linked Polyethylene (XLPE) - standard.

Insulation screen: Extruded semiconducting compound.

Metallic screen: Plain annealed copper wire. Combined screen area is designed to provide not less than 50% conductance of one associated power conductor.

Armour: Galvanised steel wires.

Outer sheath: Red 5V-90 polyvinyl chloride (PVC). Installation conditions In free air In duct In ground In trench

Installation conditions:

In free air

In duct

In ground

In trench

What standard does the Feichun 6.35/11 kV Mine Feeder Cable comply with?

The cable is fully manufactured and tested in accordance with:

AS/NZS 1972 – Electric Cables for Mining and Industrial Applications

This standard governs:

Medium-voltage insulation systems

Screened and armoured cable design

Mechanical protection for mining conditions

Fire performance and safety requirements

Compliance with AS/NZS 1972 makes this cable widely accepted in:

Australian mining projects

Heavy industrial power networks

Where is Feichun AS/NZS 1972 Mine Feeder Cable typically used?

What mining applications is this cable best suited for?

Main power feeders from surface substations

Underground distribution networks

Shaft and decline feeders

Fixed plant supply (crushers, mills, conveyors)

Heavy industrial facilities linked to mining operations

How does this cable compare with other mining feeder cable options?

AS/NZS 1972 vs flexible mining cables

Feature | AS/NZS 1972 Feeder | Flexible MV Mining Cable |

|---|---|---|

Flexibility | Rigid | Flexible |

Installation | Fixed | Reeling / trailing |

Armour | GSW | Often braid or light armour |

Mechanical protection | Very heavy | Medium |

Service life | Long-term | Medium |

Conclusion

AS/NZS 1972 feeder cables are ideal for permanent installations, not mobile equipment.

What should be considered during installation?

What is the minimum bending radius?

During installation: 12 × cable diameter

Installed position: approximately 8 × diameter

Exceeding bending limits may damage:

Insulation screens

Armour integrity

What installation environments are allowed?

In free air

In duct

Direct buried

In trench

Always consider:

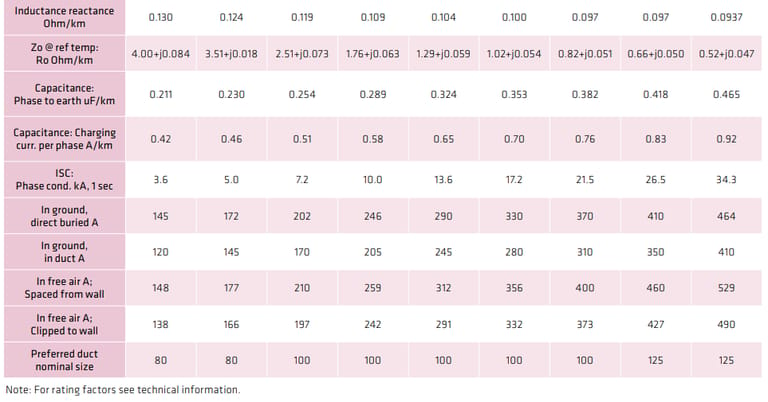

Soil thermal resistivity

Duct spacing

Pulling tension limits

How much pulling tension is allowed?

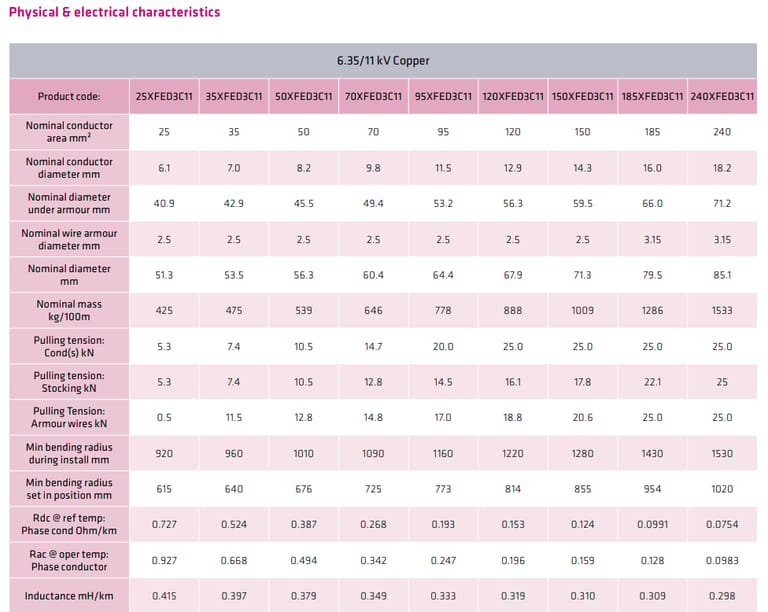

Pulling tension depends on conductor size:

Up to 25 kN for larger sizes

Armour pulling allowed within specified limits

Use:

Cable rollers

Approved pulling socks

Lubricants where necessary

Frequently Asked Questions (FAQ)

Is this cable suitable for underground mining?

Yes. It is specifically designed for primary underground power supply, with high mechanical and electrical safety margins.

Can this cable be used in chemically aggressive environments?

Yes. It offers very good resistance to chemical exposure and moisture.

Is the cable flame retardant?

Yes. The PVC sheath is flame retardant, enhancing mine safety compliance.

Is this cable suitable for solar-exposed installations?

Yes. The outer sheath has very good resistance to UV and weather exposure.

How do you choose the right size of mine feeder cable?

Consider:

Load current and future expansion

Installation method

Fault level at installation point

Voltage drop limits

Local mining regulations

Engineering calculations should always be performed before final selection.

Why choose Feichun AS/NZS 1972 Mine Feeder Cable?

Proven AS/NZS 1972 compliance

Heavy-duty construction for mining

Wide conductor size range

Suitable for harsh African and Australian conditions

Long service life and reduced maintenance cost

Need help selecting the right mine feeder cable?

Contact Feichun Cable today for:

Technical selection support

Datasheets and drawings

Project-specific cable recommendations

Export documentation for international mining projects

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: