Anhui Feichun Special Cable Co.,Ltd Li.wang@feichuncables.com

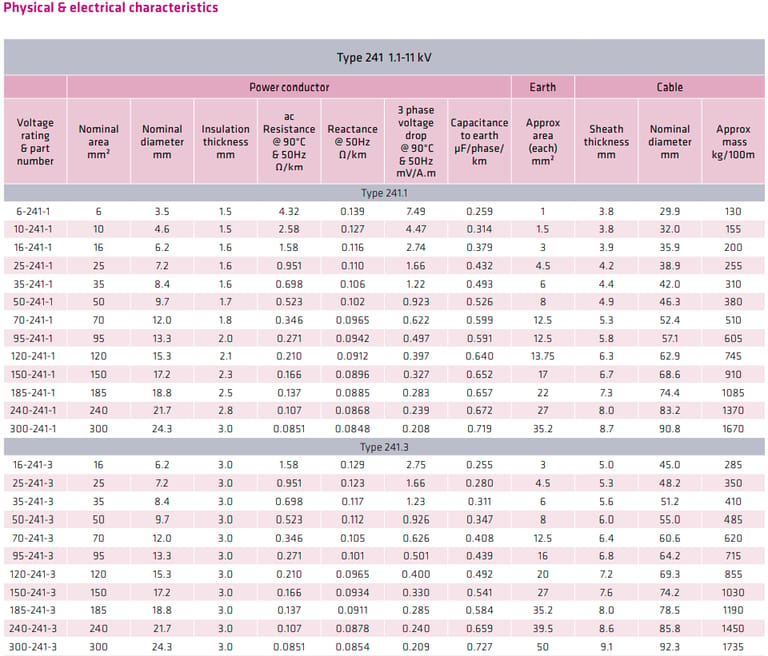

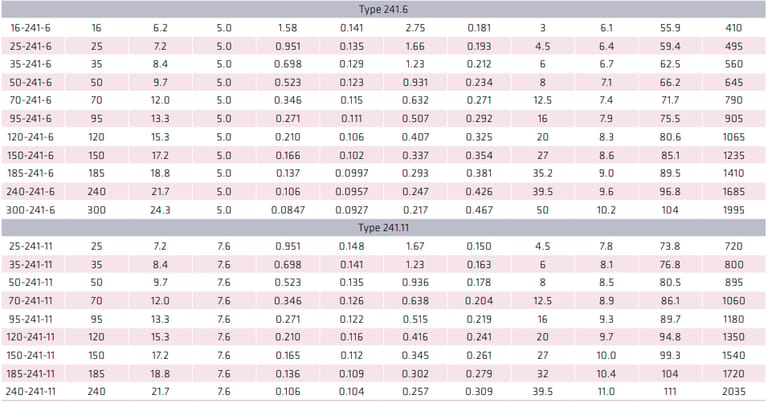

AS/NZS 1802 Type 241 1.1-11 kV UNDERGROUND MINE CABLES

Feichun AS/NZS 1802 Type 241 1.1-11 kV

Cable description:

Semiconductive screened cable for general use to AS/NZS 1802.

Application:

1.1/1.1 kV to 11/11 kV general purpose cable used for continuous miners, or feeder cables to pumps. Also commonly used for monorails supplying DCBs and longwalls. Typically, a more flexible cable for use is a semiconductive screen instead of a metal screen.

Approvals:

AS/NZS 1802

Behaviour in flame and fire:

Fire retardant Temperature range Maximum operating temperature: +90°C

Minimum operating temperature: -25 °C

Flexibility:

Flexible

Resistance to:

Chemical exposure: Very good/Frequent

Mechanical impact: Heavy

Water exposure: Immersion/Temporary coverage

Solar radiation and

weather exposure: Suitable for direct exposure

Cable design:

Semiconductive elastomer screened power cores, with three earth cores and one extensible pilot.

Core: Metal: tinned copper, three core three earths plus central pilot.

Conductor separator tape:

1.1/1.1 kV – polyester where necessary.

3.3 kV and above – semiconductive screen.

Insulation: EPR (R-EP-90) core with durably printed core numbers at intervals less than 300 mm, on black semiconductive insulation screen for phase identification

Screen: Semiconductive elastomer screen.

Pilot: Single, in centre of cable.

Maximum DC resistance; 5.5 Ω/100 m for power cores to 35 mm². 3 Ω/100 m for power conductors above 35 mm².

Earth: Three semiconductive elastomer covered flexible earths, located in the interstices.

Sheath: Open weave reinforcement, under heavy duty HD-85-PCP. Installation conditions In free air In duct Mobile equipment Machines

Installation conditions:

In free air

In duct

Mobile equipment

Machines

What Makes Feichun AS/NZS 1802 Type 241 Mining Cable Different from Other Mining Cables?

AS/NZS 1802 Type 241 mining cable is a semiconductive elastomer screened flexible power cable designed for medium-voltage mining applications ranging from 1.1 kV up to 11 kV. Unlike metal-screened designs, Type 241 uses a semiconductive screen, offering a balance between electrical performance, flexibility, and mechanical robustness—a combination that is particularly valuable in underground and mobile mining environments.

Feichun’s Type 241 cable is widely used for:

Continuous miners

Feeder cables to pumps

Monorails supplying Distribution Control Boxes (DCBs)

Longwall mining systems

Its compliance with AS/NZS 1802, proven flame-retardant behaviour, and excellent resistance to mechanical, chemical, and environmental stresses make it a trusted solution in Australian and South African mining operations.

What Applications Is Type 241 Mining Cable Designed For?

Type 241 is classified as a general-purpose medium-voltage mining cable, but its design clearly targets dynamic, mechanically demanding applications.

Typical Use Scenarios

Continuous miners requiring flexible, screened power supply

Underground pump feeders in wet or chemically aggressive conditions

Monorail systems supplying power to DCBs

Longwall face equipment, where repeated bending and movement occur

Because the cable uses a semiconductive elastomer screen instead of a metallic screen, it is typically more flexible and easier to handle during installation and relocation.

How Does Type 241 Compare with Other AS/NZS Mining Cable Types?

Comparison Table: Type 241 vs Type 240 vs Type 210

Feature | Type 241 | Type 240 | Type 210 |

|---|---|---|---|

Voltage range | 1.1–11 kV | 3.3–11 kV | 1.1 kV |

Screen type | Semiconductive | Metallic | Unscreened |

Flexibility | High | Medium | High |

Typical use | Mobile & feeders | Fixed feeders | Low-voltage machines |

Installation stress | Heavy duty | Heavy duty | Moderate |

Type 241 is often chosen when flexibility and screened performance are required without the stiffness of metallic screens.

How Is Type 241 Installed in Mining Environments?

What Installation Conditions Are Suitable?

Feichun Type 241 cables are suitable for:

Installation in free air

Duct installations

Mobile mining equipment

Fixed or semi-fixed machines and feeders

Installation Best Practices

Maintain adequate minimum bending radius, especially for larger cross-sections

Avoid sharp edges and unprotected steel supports

Ensure correct earthing and pilot core termination

Regularly inspect sheath integrity in high-impact zones

Proper installation significantly extends cable life and reduces unplanned downtime.

How Is Type 241 Used in Real South African Mining Projects?

Case Study: Platinum Mine in Limpopo Province

In a deep-level platinum mine in Limpopo, Type 241.6 (6.6 kV) cables were selected to power:

Underground pump stations

Monorail-mounted DCBs

Mobile auxiliary equipment

Key reasons for selection:

Superior flexibility in confined tunnels

Reliable operation under wet and abrasive conditions

Compliance with site safety standards aligned with AS/NZS and local mining regulations

After installation, the mine reported reduced cable failures and lower maintenance costs compared to older metal-screened alternatives.

Frequently Asked Questions About AS/NZS 1802 Type 241 Mining Cable

Is Type 241 suitable for continuous miners?

Yes. Its flexibility, screened design, and mechanical strength make it ideal for continuous mining equipment.

Can Type 241 be used in wet underground conditions?

Yes. The cable is suitable for immersion and temporary water coverage.

Why choose semiconductive screening instead of metallic screening?

Semiconductive screens offer greater flexibility and fatigue resistance, especially for mobile applications.

What is the maximum operating temperature?

The maximum continuous operating temperature is +90 °C.

Is Type 241 compliant with AS/NZS 1802?

Yes. It is fully designed and approved to AS/NZS 1802.

Why Choose Feichun for Type 241 Mining Cables?

Feichun combines:

Proven AS/NZS 1802 compliance

Broad voltage and size ranges

Mining-grade materials and construction

Experience supporting African and Australian mining projects

Whether you are upgrading feeder systems or powering mobile mining equipment, Feichun Type 241 offers a balanced, reliable, and cost-effective solution.

Ready to Select the Right Type 241 Cable for Your Mine?

If you need technical datasheets, sizing assistance, or project-specific recommendations for AS/NZS 1802 Type 241 mining cables, contact Feichun today. Our engineering team can help you choose the optimal voltage class and conductor size for your mining operation.

Feichun Mining Cable

Durable mining cables for tough environments and operations

Contact us:

© 2025. All rights reserved.