Anhui Feichun Kabel Khusus Co., Ltd

AS/NZS 1802 Type 240 1.1-11 kV

AS/NZS 1802 Type 240 1.1-11 kV

Cable description:

Composite screened cable for general use to AS/NZS 1802.

Application:

1.1/1.1 kV to 11/11 kV cable used extensively for feeder connection between transformer and gate-end box or similar, continuous miner cable or feeder cables to pumps. Having three pilots, the cable can be used in long runs, without compromising pilot control protection system resistance limitations. For applications requiring high degrees of flexibility, Type 241 cables would be more appropriate.

Approvals:

AS/NZS 1802

Behaviour in flame and fire:

Fire retardant

Temperature range:

Maximum operating temperature: +90°C

Minimum operating temperature: -25 °C

Flexibility:

Flexible

Resistance to:

Chemical exposure: Very good/Frequent

Mechanical impact: Heavy

Water exposure: Immersion/Temporary coverage

Solar radiation and

weather exposure: Suitable for direct exposure

Cable design:

Composite screened power cores and three separate pilot conductors.

Core: Metal: tinned copper, three core plus central pilot.

Conductor separator tape: 1.1/1.1 kV – polyester. 3.3 kV and above – semiconductive tape.

Insulation: EPR (R-EP-90).

Insulation tape: 1.1/1.1 kV – proofed textile. 3.3 kV and above – semiconductive screen.

Screen: Composite screen (earth) of tinned annealed copper wire and polyester yarn. Core colours: red, white, blue braid tracers Pilot: Three in the interstitial cavities elastomer covered and proofed taped.

Sheath: Heavy duty HD-85-PCP. Sheath reinforcement is available upon request.

Installation conditions:

In free air

In duct

Mobile equipment

Machines

What Makes AS/NZS 1802 Type 240 Different from Other Mining Cables?

Unlike standard flexible mining cables, Type 240 is a composite-screened underground cable designed for long feeder runs and pilot-controlled systems.

Key distinguishing features include:

Voltage range from 1.1 kV up to 11 kV

Three power cores + three pilot conductors

Composite earth screen for enhanced fault protection

Heavy-duty PCP outer sheath for mechanical and chemical resistance

If high flexibility is the primary requirement, AS/NZS Type 241 is often preferred. However, when electrical integrity, pilot monitoring, and long-distance feeder performance matter most, Type 240 becomes the go-to solution.

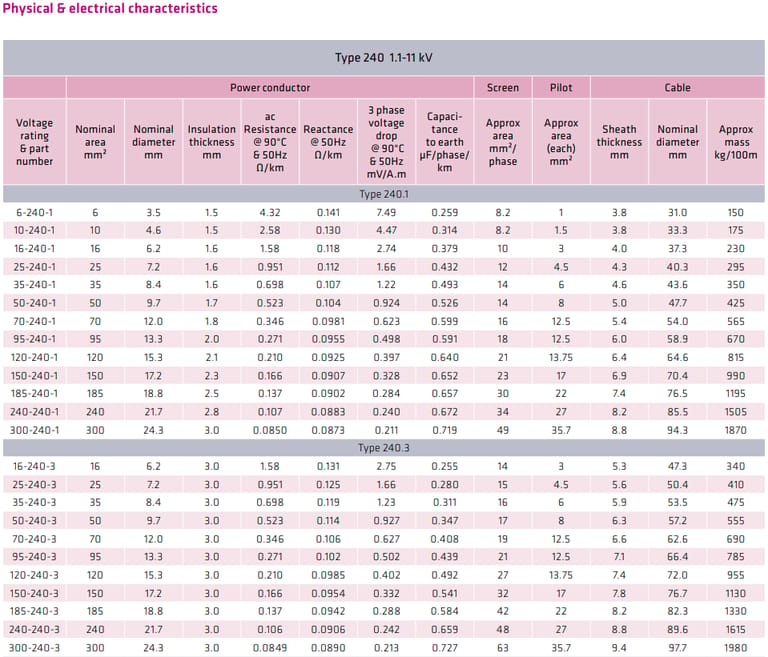

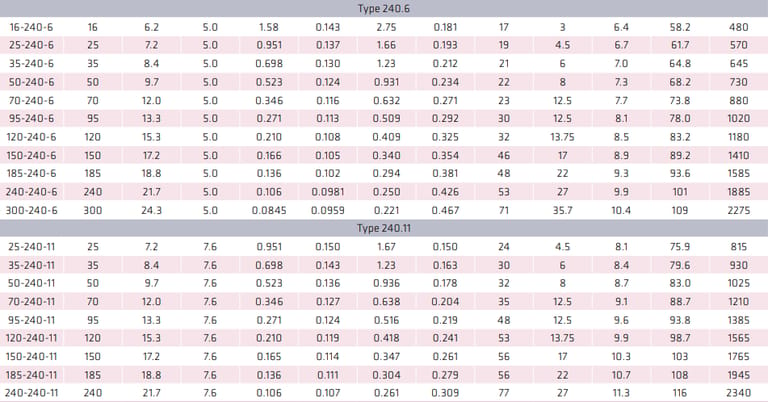

What Are the Key Electrical and Physical Specifications?

What Voltage Ratings Are Available?

Feichun Type 240 covers a broad voltage range:

1.1/1.1 kV

3.3 kV

6.6 kV

11 kV

This makes it suitable for both low-voltage and medium-voltage underground distribution systems.

How Do Electrical Parameters Affect Performance?

Key electrical characteristics include:

Low AC resistance at 90 °C, reducing losses

Stable reactance at 50 Hz, supporting long feeder runs

Controlled capacitance to earth, minimizing charging currents at higher voltages

For example, a 240 mm², 11 kV Type 240 cable offers:

AC resistance ≈ 0.106 Ω/km

Voltage drop ≈ 0.261 mV/A·m

Capacitance ≈ 0.309 μF/phase/km

These values ensure efficient power delivery with minimal voltage drop, even over extended distances.

Where Is AS/NZS Type 240 Commonly Used in Underground Mines?

What Are the Typical Applications?

Feichun Type 240 mining cables are widely used for:

Transformer to gate-end box feeders

Continuous miner supply cables

Pump stations in underground roadways

Fixed and semi-mobile mining machinery

The cable is suitable for installation:

In free air

In ducts

On mobile equipment

On fixed machines

How Does Type 240 Perform in Harsh Mining Conditions?

Type 240 is engineered to withstand:

Heavy mechanical impact

Frequent chemical exposure

Temporary water immersion

Direct solar radiation (surface transitions)

Its HD-85 PCP sheath provides excellent abrasion resistance, while optional sheath reinforcement can be specified for extreme conditions.

How Does Type 240 Compare with Other AS/NZS Mining Cables?

Type 240 vs Type 241: Which Should You Choose?

Feature | Type 240 | Type 241 |

|---|---|---|

Voltage range | 1.1–11 kV | 1.1–11 kV |

Flexibility | Flexible | Extra flexible |

Typical use | Feeders & fixed runs | Highly mobile equipment |

Pilot system | Three pilots | Three pilots |

Best for | Long runs, stability | Frequent movement |

Recommendation:

Choose Type 240 for long underground feeders and Type 241 where constant movement is required.

What Should Be Considered During Installation?

What Are the Best Installation Practices?

To maximize service life:

Maintain minimum bending radius during pulling

Avoid twisting that may stress composite screens

Use proper cleating to prevent sheath abrasion

Ensure correct earthing of composite screen

Verify pilot continuity before energization

For duct installations, ensure:

Smooth duct interiors

Adequate pulling lubricant

Controlled pulling tension

Frequently Asked Questions (FAQ)

Can Type 240 Be Used for Mobile Mining Equipment?

Yes, but only for limited movement. For constant trailing applications, Type 241 or reeling cables are better suited.

Is Type 240 Flame Retardant?

Yes. The cable is fire retardant and complies with AS/NZS 1802 flame behavior requirements, enhancing underground safety.

What Temperature Range Can Type 240 Handle?

Maximum operating temperature: +90 °C

Minimum operating temperature: −25 °C

This makes it suitable for both deep underground and surface transition areas.

Does Type 240 Support Long Pilot Circuits?

Yes. The three-pilot design enables long feeder runs without exceeding pilot system resistance limits, a major advantage in large mines.

Why Choose Feichun AS/NZS Type 240 Mining Cable?

Feichun Type 240 offers:

Full compliance with AS/NZS 1802

Proven performance in South African mining conditions

Robust composite screening for safety

Broad voltage and size range

Custom options including sheath reinforcement

Call to Action: How Do You Select the Right Type 240 Cable Size?

Selecting the correct conductor size and voltage rating depends on:

Load current

Feeder length

Voltage drop limits

Installation method

👉 Contact Feichun’s technical team to receive:

Cable sizing calculations

Datasheets and drawings

Project-specific recommendations

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: