Anhui Feichun Kabel Khusus Co., Ltd

AS/NZS 1802 Type 210 1.1 kV

AS/NZS 1802 Type 210 1.1 kV

Cable description:

Composite screened cable for hand-held equipment to AS/NZS 1802.

Application:

1.1/1.1 kV cable used primarily for hand-held boring machines, and as a flexible lead to other equipment where heavy duty service is required. Note, certain regulatory authorities limit the use of this cable to 250/250V.

Approvals:

AS/NZS 1802

AS/NZS 5000.1

Behaviour in flame and fire:

Fire retardant

Temperature range:

Maximum operating temperature: +90°C

Minimum operating temperature: -25 °C

Flexibility:

Flexible

Resistance to:

Chemical exposure: Very good/Frequent

Mechanical impact: Heavy

Water exposure: Immersion/Temporary coverage

Solar radiation and

weather exposure: Suitable for direct exposure

Cable design:

Composite screened power cores with a single extensible pilot.

Core: Metal: tinned copper, three core plus central pilot.

Insulation: EPR (R-EP-90).

Screen: Composite screen (earth) of tinned annealed copper wire and polyester yarn.

Core colours: red, white, blue braid tracers

Pilot: Single, in centre of cable. Pilot resistance is ≤ 5.5 Ω/100 m.

Sheath: Heavy duty HD-85-PCP.

Installation conditions

In free air

In duct

Machines

What Does “AS/NZS 1802 Type 210” Mean in Mining Cable Classification?

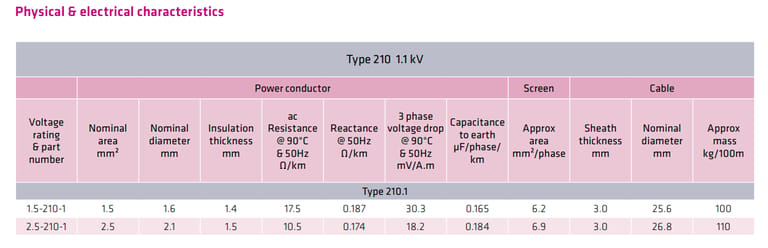

The designation AS/NZS 1802 Type 210 refers to a cable type defined under the Australian/New Zealand standard AS/NZS 1802, which specifies requirements for reeling, trailing, and underground mining cables.

Type 210 cables are characterised by:

Composite earth screening

Central extensible pilot conductor

Flexible EPR insulation

Heavy-duty PCP outer sheath

Nominal voltage rating of 1.1/1.1 kV

These features make Type 210 suitable for portable and hand-held mining equipment where safety, flexibility, and mechanical robustness are critical.

What Is the Typical Application of a Type 210 1.1 kV Mining Cable?

Why Is Type 210 Commonly Used for Hand-Held Boring Machines?

The primary application of the Feichun Type 210 cable is as a power supply cable for hand-held boring machines, roof bolters, and similar underground tools. These machines require:

Continuous flexing resistance

Reliable earth continuity

Pilot conductor protection for control and safety circuits

The composite screen and central pilot ensure effective earth fault detection and compliance with mining safety practices.

Where Else Can Type 210 Be Used?

Beyond hand-held tools, Type 210 is also used as a:

Flexible lead to mobile mining equipment

Temporary power supply cable in underground workings

Connection cable in harsh mechanical conditions

How Does Type 210 Compare with Other Mining Cable Types?

Type 210 vs Type 241: What’s the Difference?

Feature | Type 210 | Type 241 |

|---|---|---|

Voltage rating | 1.1 kV | Up to 3.3 kV |

Typical use | Hand-held tools | Mobile plant |

Screen type | Composite | Metallic |

Flexibility | Very high | Moderate |

Type 210 vs Type 245: Which Should You Choose?

Type 210 is better suited for portable equipment, while Type 245 is designed for higher power fixed installations.

How Should a Type 210 Mining Cable Be Installed?

Can Type 210 Be Installed in Free Air or Ducts?

Yes. Approved installation conditions include:

Free air

Duct installation

Direct connection to machines

What Installation Practices Improve Service Life?

Avoid sharp bending radii

Use proper cable cleats to prevent abrasion

Protect terminations from moisture ingress

Inspect pilot continuity regularly

Frequently Asked Questions About Type 210 Mining Cables

Is Type 210 suitable for continuous flexing?

Yes. It is designed for frequent movement and bending, making it ideal for hand-held tools.

Can Type 210 be submerged in water?

Yes. It is suitable for temporary water immersion, but long-term submersion should be evaluated case by case.

Is the cable flame retardant?

Yes. The PCP sheath is fire retardant, enhancing underground safety.

Why is a pilot conductor necessary?

The pilot conductor supports control circuits and earth monitoring, which are critical for mine safety systems.

What Should Buyers Consider Before Selecting a Type 210 Cable?

Confirm local regulatory voltage limitations

Match conductor size to load and distance

Ensure pilot resistance meets system requirements

Choose a manufacturer with mining-specific experience

Why Choose Feichun AS/NZS 1802 Type 210 Mining Cable?

Feichun’s Type 210 cable combines:

Proven AS/NZS 1802 compliance

Robust materials for harsh mining conditions

Reliable electrical performance

Field-tested success in international mining projects

Call to Action: Need Technical Support or a Quotation?

If you are selecting cables for underground mining, hand-held equipment, or mobile machinery, our technical team can help you:

Select the correct conductor size

Verify regulatory compliance

Provide tailored quotations and datasheets

Contact Feichun today to ensure safe, reliable, and compliant mining power solutions.

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: