Anhui Feichun Kabel Khusus Co., Ltd

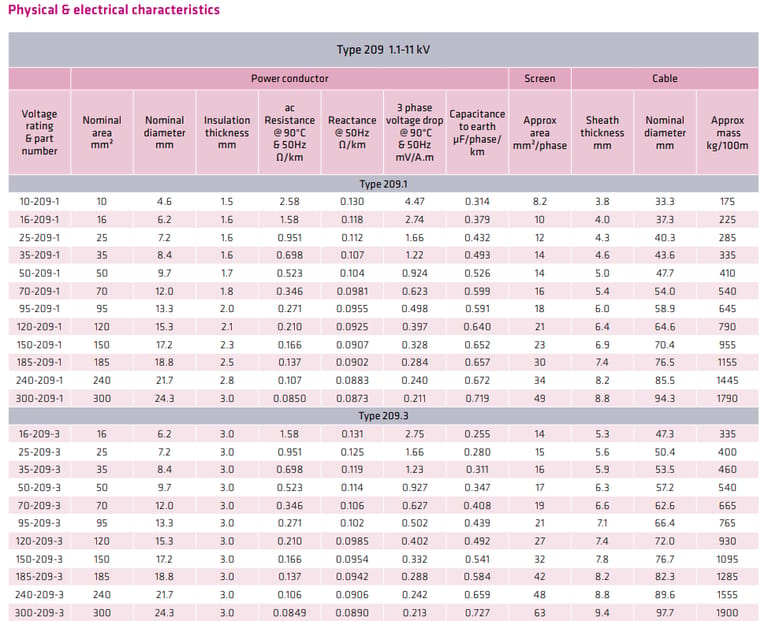

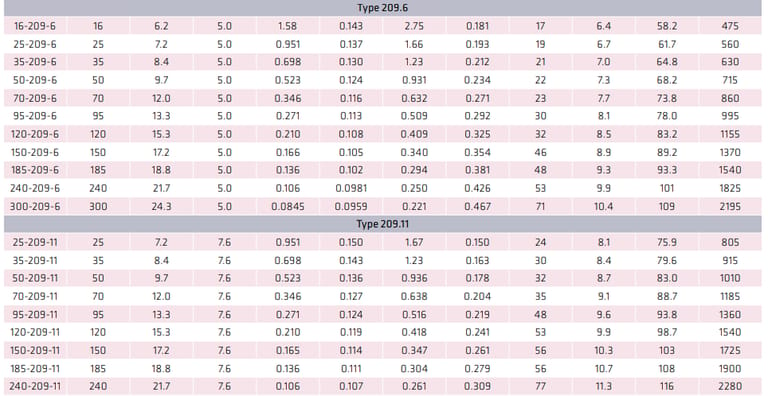

AS/NZS 1802 Type 209 1.1-11 kV Mining Cable

Feichun AS/NZS 1802 Type 209 1.1-11 kV Mining Cable

Cable description:

Composite screened cable for general use to AS/NZS 1802.

Application:

1.1/1.1 kV to 11/11 kV general cable used extensively for feeder connection between transformer and gate-end box or similar, or feeder cables to pumps, fans, crushers, etc or as a substitute to Type A or B feeder cables. This cable can also be used above ground for power supply to mobile equipment.

Approvals: AS/NZS 1802 AS/NZS 1972 AS/NZS 5000.1

Behaviour in flame and fire: Fire retardant

Temperature range:

Maximum operating temperature: +90°C

Minimum operating temperature: -25 °C

Flexibility: Flexible

Resistance to:

Chemical exposure: Very good/Frequent

Mechanical impact: Heavy

Water exposure: Immersion/Temporary coverage

Solar radiation and

weather exposure: Suitable for direct exposure

Cable design:

Composite screened cores with a single extensible pilot.

Core: Metal: tinned copper, three core plus central pilot.

Conductor separator tape: 1.1/1.1 kV – polyester. 3.3 kV and above – semiconductive screen.

Insulation: EPR (R-EP-90). Insulation tape: 1.1/1.1 kV – proofed textile. 3.3 kV and above – semiconductive screen.

Screen: Composite screen (earth) of tinned annealed copper wire and polyester yarn.

Core colours: red, white, blue braid tracers.

Pilot: Single, in centre of cable.

Maximum DC resistance; 5.5 Ω/100 m for power cores to 35 mm². 3 Ω/100 m for power conductors above 35 mm².

Sheath: Heavy duty HD-85-PCP Sheath reinforcement is available upon request.

Installation conditions:

In free air

In duct

Mobile equipment

Machines

What Are the Core Features and Design of Feichun Type 209 Mining Cable?

The Feichun AS/NZS 1802 Type 209 is a composite screened cable, designed for general use according to AS/NZS 1802 standards. Its core features include:

Conductor Material: Tinned copper, three cores plus a central pilot wire.

Insulation: Ethylene Propylene Rubber (EPR/R-EP-90), ensuring flexibility and thermal stability.

Screening: Composite copper and polyester braid for earth continuity and electromagnetic protection.

Sheath: Heavy-duty HD-85-PCP, providing excellent mechanical and chemical resistance.

Flexibility: Flexible enough for mobile equipment applications.

Its composite screened design reduces electromagnetic interference (EMI) while maintaining safety and performance under heavy mechanical stress, immersion in water, and exposure to chemicals and UV radiation.

What Applications Are Feichun Type 209 Cables Best Suited For?

Type 209 cables are highly versatile and suitable for a range of applications:

Feeder Cables: Connection between transformers and gate-end boxes.

Powering Mining Equipment: Pumps, fans, crushers, and mobile machines.

Substitute for Type A or B Feeder Cables: Where similar power ratings and flexibility are required.

Above Ground Applications: Providing power to mobile or temporary equipment setups.

In South Africa, these cables have been successfully deployed in gold and platinum mines, particularly for high-flexibility feeder connections between underground substations and mobile equipment such as pumps and ventilation fans.

What Makes Type 209 Cables Durable in Harsh Mining Environments?

Feichun Type 209 cables are designed to withstand extreme mechanical, chemical, and environmental stresses:

Chemical Resistance: Excellent resistance to acids, oils, and solvents common in mining.

Mechanical Strength: Can handle heavy impacts and frequent handling during installation and operation.

Water and Immersion Resistance: Suitable for temporary or accidental immersion.

UV and Weather Resistance: Designed for outdoor exposure without degradation.

This combination of features ensures that Type 209 cables maintain reliability and safety in South Africa’s challenging mining environments.

How Does Type 209 Compare to Type A and Type B Feeder Cables?

While Type A and B are commonly used in mining for feeder applications, Type 209 offers some distinct advantages:

Feature | Type A | Type B | Type 209 |

|---|---|---|---|

Flexibility | Moderate | High | High |

Voltage Range | 1.1–11 kV | 1.1–11 kV | 1.1–11 kV |

Mechanical Resistance | Medium | Medium | High |

Chemical Resistance | Moderate | Moderate | Very Good |

Screen Type | Single | Single | Composite Copper & Polyester |

Ideal Application | Standard feeders | Flexible feeders | Feeder + Mobile equipment + Above-ground |

Type 209 is particularly advantageous where mechanical impact, chemical exposure, or mobile equipment usage is expected, providing a more robust and versatile solution.

Frequently Asked Questions (FAQ)

Can Type 209 Cables Replace Type A or B Feeder Cables?

Yes. Type 209 is fully compatible as a substitute for Type A or B feeders, especially where increased mechanical or chemical resistance is required.

How Flexible Are Type 209 Cables for Mobile Equipment?

Type 209 is highly flexible due to its EPR insulation and composite screening. For applications with frequent movement, reinforced sheath options are recommended.

Can Type 209 Be Used Above Ground?

Absolutely. The cable’s UV and weather-resistant sheath makes it suitable for temporary or permanent above-ground installations powering mobile machinery.

What Are the Maximum Power Conductor Sizes Available?

Type 209 supports power conductors from 10 mm² to 300 mm², covering a wide range of mining power distribution requirements.

How Does Voltage Drop Affect Mining Operations?

Low voltage drop ensures stable operation of pumps, crushers, and ventilation fans. Type 209’s low resistance and reactance minimize energy loss over long feeder runs.

What Are the Advantages of Composite Screened Design?

Enhanced Safety: Provides low-resistance earth path, reducing shock hazard.

Electromagnetic Shielding: Minimizes interference with control signals.

Mechanical Support: Composite braid protects cores from damage during installation.

How to Choose the Right Type 209 Variant for Your Application?

Type 209.1: Standard installations, light mechanical stress.

Type 209.3: Moderate flexibility, suitable for fixed and semi-mobile equipment.

Type 209.6: High flexibility, suitable for frequently moved machinery.

Type 209.11: Extra mechanical and voltage rating for high-stress applications.

Why Choose Feichun Type 209 Mining Cables?

Versatile Application: Underground feeders, mobile equipment, above-ground power supply.

Durable Design: Resistant to fire, chemicals, water, UV, and mechanical impact.

Flexible Installation: Available in multiple variants to meet mobility and voltage requirements.

If you are planning to upgrade your mine’s power distribution system or require flexible feeder cables for mobile equipment, Feichun Type 209 offers a robust, fire-retardant, and flexible solution.

Kabel Pertambangan Feichun

Kabel pertambangan yang tahan lama untuk lingkungan dan operasi yang berat

Alamat Email

© 2025. All rights reserved.

Produk

Kabel Tambang AS/NZS

Kabel Tambang DIN VDE

Kabel Tambang BS 6708

Kabel Tambang ICEA & CAN/CSA

Kabel Berselubung Baja

Kabel Gulung / Kabel Reeling

Kabel Festoon / Kabel Rel Kren

Perusahaan

Kontak

WhatsApp: +86 17333223430

Social Media: